Centrifugal pumps are used in a very wide range of industries, from chemical-petrochemical to textile to water treatment, electronic, etc.

If you are looking for accurate and specific information regarding centrifugal pumps, you are in the right place! In the following paragraphs, in fact, we are going to explain their characteristics and how they work.

Centrifugal pumps: classification

Based on the position of the drive shaft that moves the impeller, there are two types of centrifugal pumps:

- horizontal pumps

- vertical pumps: suitable for applications where installation of the pump semi-submersed in the liquid is required (tanks, reservoirs, sumps etc.)

Horizontal centrifugal pumps can be installed:

- above the fluid level: in this case, the pump has to be self-priming

- below the fluid level: the pump is installed below the liquid level so it is flooded

Centrifugal pumps are composed of an impeller, assembled on the motor shaft, which rotates inside the pump head. The liquid enters in the axial direction but different types of pumps have different outflow directions:

- Radial flow pumps (most common)

- Axial flow pumps

- Mixed flow pumps

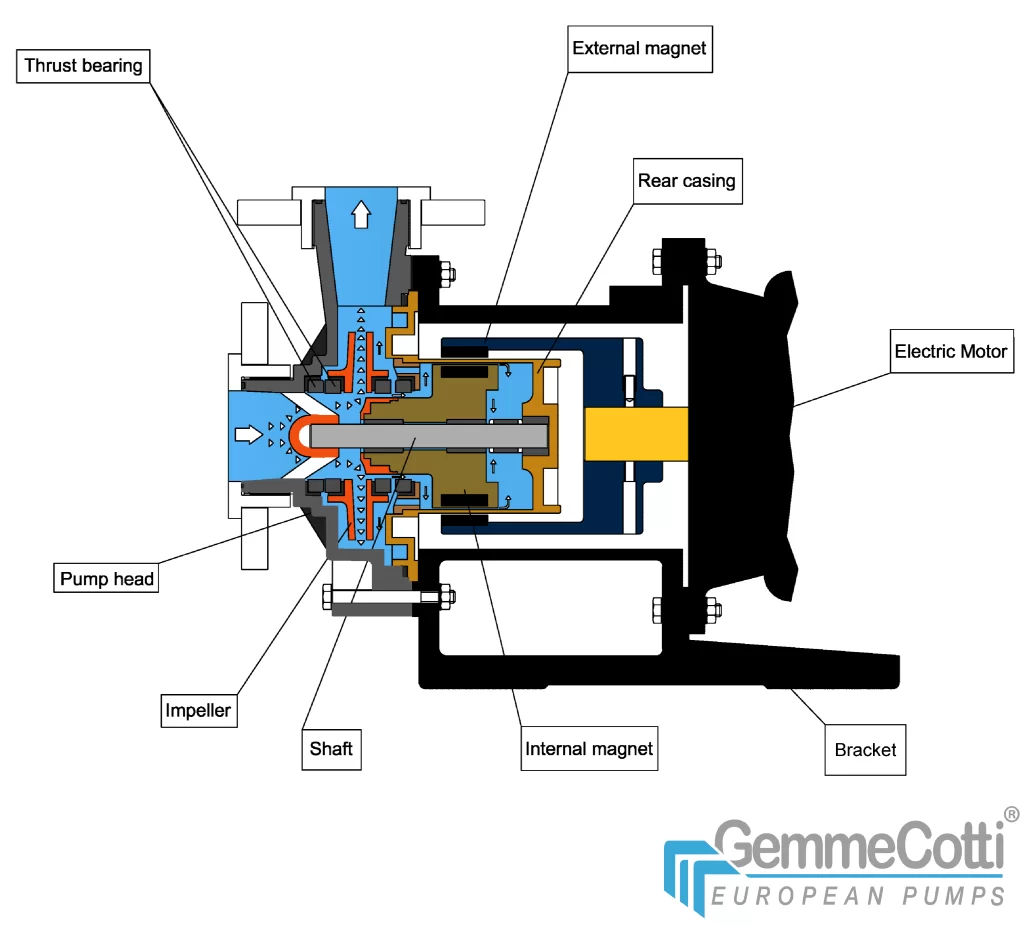

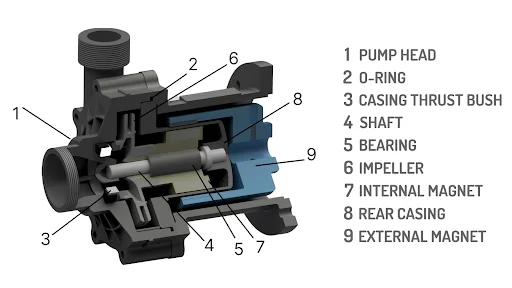

Centrifugal pumps: components

The main components are:

- the pump head (or pump casing)

- the impeller, which is connected to the motor shaft. You can choose between different types of impellers for centrifugal pumps: open, which is used with liquids with a higher concentration of impurities; closed, when there is a smaller percentage of suspended solids; semi-open etc.

- the shaft

- the motor

- Sealing system to prevent liquid leakage between the pump head and the shaft

There are different types of sealing systems, such as:

- mechanical seal pumps, in which the pump shaft, connected to the impeller, exits to the outside to be connected to the motor, and a mechanical seal is installed to ensure sealing

- mag drive centrifugal pumps in which the external magnet is assembled directly on the motor shaft and it transmits motion to the impeller by means of an internal magnet through magnetic force. In this case, the shaft does not pass to the outside of the pump.

The external magnet placed on the drive shaft transmits the motion to the internal magnet connected to the impeller which rotates and moves the fluid through the pump. So the containment rear casing contains the internal magnet mentioned above and it ensures a hermetic seal on the hydraulic part of the pump, keeping it separated from the motor.

The figure below shows the main components of these pumps:

Centrifugal pumps: functioning

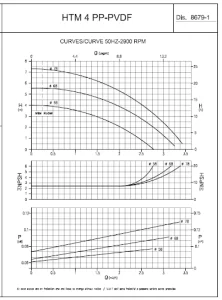

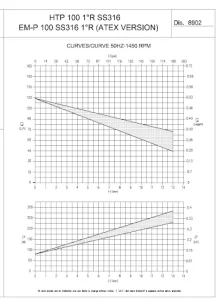

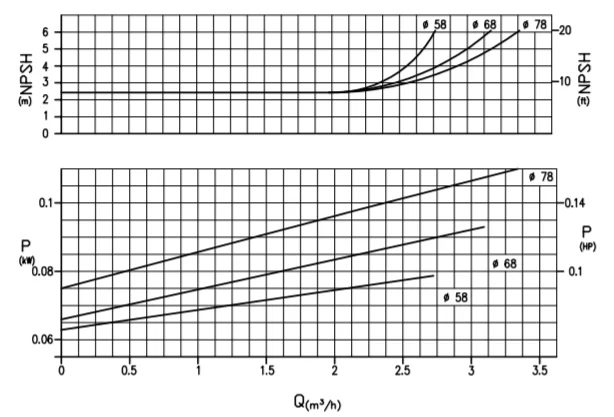

How does a centrifugal pump work? Operating curves and graphs can be used to describe their performance and area of work.

For a centrifugal pump, the performance curves can be seen in graph 4.1 while graph 4.2 shows the case of a positive displacement pump:

The top graph in both figures describes the head variation given by the pumps as the flow rate changes. The best performance is recorded by working centrally, both on the x-axis and y-axis. So between 2 and 2.5 m3/h and between a head of 4 and 5 m.

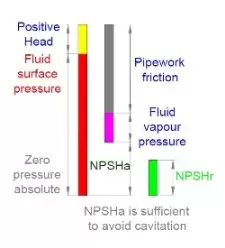

For the proper functioning of a centrifugal pump plant, it is necessary to verify that the NPSH available in the plant is higher than the NPSH required by the pump.

We will not expand on the explanation of NPSH here but you can refer to the following link: https://www.gemmecotti.com/npsh-a-brief-explanation/

GemmeCotti centrifugal pumps

GemmeCotti can supply four different models of mag drive pumps and one model of mechanical seal pumps:

HTM PP/PVDF and HCM PP/PVDF – MAG DRIVE CENTRIFUGAL PUMPS

- thermoplastic pumps made in PP or PVDF

- capacity up to 130 m3/h

- head up to 48 mlc

- HTM : injection molded parts – HCM: casing machined from a block

HTM SP – SELF-PRIMING MAG DRIVE CENTRIFUGAL PUMPS

- thermoplastic pumps made in PP or PVDF

- capacity up to 25 m3/h

- head up to 22 mlc

- injection molded parts

- self-priming up to 6 m

HTM SS 316 – AISI 316 MAG DRIVE CENTRIFUGAL PUMPS

- thermoplastic pumps made in AISI 316

- capacity up to 32 m3/h

- head up to 24 mlc

HCO – MECHANICAL SEAL CENTRIFUGAL PUMPS

- thermoplastic pumps made in PP or PVDF

- Flow up to 130 m3/h

- Head up to 48 mlc