NPSH (net positive suction head) is one of the main parameters to be considered when selecting a pump. But what are we referring to when we talk about NPSH? And why is it so important?

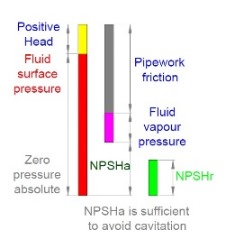

First of all, we have to distinguish two different values of NPSH: the NPSH available and the NPSH required.

NPSH AVAILABLE

The NPSH available, normally shortened as NPSHa, is a value calculated by the plant engineer. It could be roughly defined as the result of the absolute pressure of a fluid at the inlet of a pump minus the vapour pressure of the liquid. It is usually expressed in meters.

NPSH REQUIRED

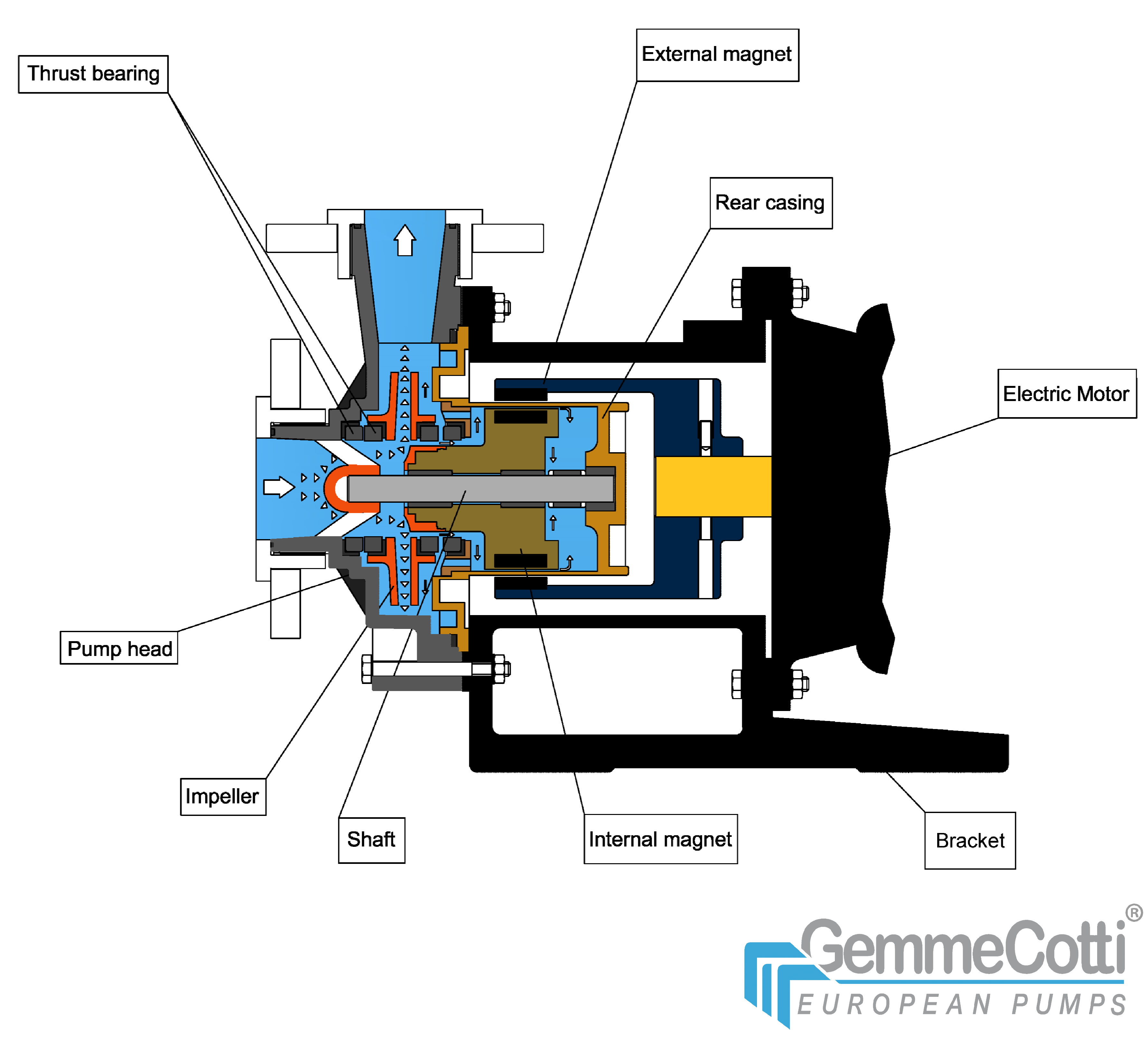

The NPSH required (NPSHr) is a value that is given by the pump supplier and describes the energy losses that often occur inside the pumps when the liquid enters through the impeller eye of the pump. The value is expressed as a head of fluid (usually in meters). This is a requirement of the pump and it depends on different factors: the design and dimensions of the impeller, the speed of the pump,

the speed of the flow rate, and so on.

NPSH: WHY IS IT SO IMPORTANT?

As we said, NPSH is fundamental in selecting and sizing a pump. Indeed, NPSHa has to be higher than NPSHr for the pump to work properly. If not, cavitation could occur, reducing the performance of the pump and, in many cases, seriously damaging it.

Cavitation is a physical phenomenon that can happen in a pump. It causes the formation of little gas bubbles inside the liquid when the system pressure goes below the vapour pressure of the fluid. These bubbles instantly collapse when the fluid is inside the impeller, beyond the impeller inlet, due to the increasing of the pressure. The collapse produces microjets with a very high impact on the impeller, which gets significantly damaged. Because the impeller is unbalanced, vibrations and all the related issues can arise: seal failure and bearings serious damaging.

NPSHa > NPSHr

For this reason, the plant engineer has to keep NPSH values in mind at all times. The pump performance curve usually includes a NPSHr graph so that the engineer can check the operating conditions. As a matter of fact, it’s necessary for the NPSHr of the pump to be lower than NPSHa in the plant. The safety margin between NPSHr and NPSHa has to be minimum of 0.5 meters.

Only if this ratio is respected the pump will work properly and cavitation will be avoided.