Since 1992 GemmeCotti has been manufacturing several types of high quality chemical pumps suitable for most industrial applications.

Everyday we employ all our experience to improve the existing products and to design new projects in order to satisfy our customers’ needs. We live in the present and we design the pumps of the future without forgetting where we started.

The magnetic drive centrifugal pump HTM PP/PVDF was our first product, the one which made us experts in the field of the pumping solutions.

Over the years we developed the series that now includes 9 sizes: HTM 4, HTM 6, HTM 10, HTM 15, HTM 31, HTM 40, HTM 50, HTM 80, HTM 100. Each size is available in two thermoplastic materials: PP (polypropylene) and PVDF.

The HTM are high-quality pumps, extremely reliable and versatile, and they are still our bestsellers.

Which are the 7 strong points of these mag drive centrifugal pumps?

1. MATERIALS OF CONSTRUCTION

The HTM pumps are manufactured in thermoplastic materials, PP or PVDF. These anti-corrosion materials are compatible with the great majority of the acids, chemicals and dangerous liquids.

Check the chemical compatibility chart

2.INJECTION MOULDING

The plastic parts of our HTM are manufactured by Gemme Plast, another company in the GemmeCotti group, which is specialized in the injection moulding of plastic. Thanks to this cooperation, we can check all the raw materials used and we have total control over the moulding process.

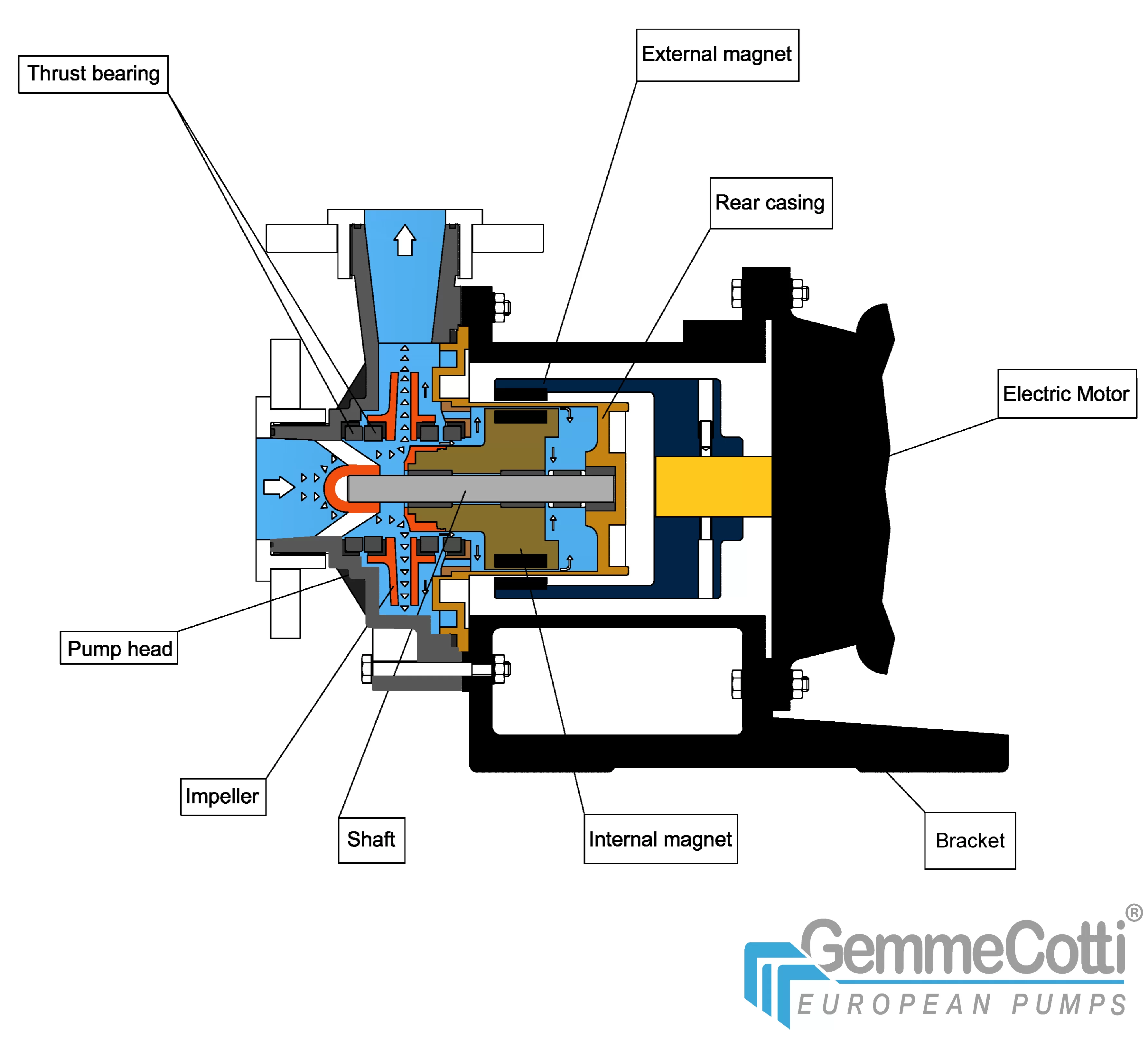

3.LEAKLESS MAGNETIC DESIGN

Advantages of the magnetic drive system:

- no mechanical seal

- no leakage or emissions

- no waste of liquids

- environmental sustainability

- reliability and safety

- low maintenance and consequent long term savings

- no need for a pump-motor alignment

Please note that the liquid must be clean and without solids in suspension (acceptable quantity and dimensions of the solids: max 2% – max 1mm).

Discover more about the mag drive advantages

4.RELIABILITY

Unlike most centrifugal pumps on the market, the pump head of the HTM is secured to the bracket with 8 bolts. This feature allows the safe fastening of the pump head, ensuring the static seal and avoiding the deformation of the pump head due to the pressure.

5.BEARINGS

The wide dimensions of the frontal bearings ensure the high resistance to the axial thrusts.

6.STATIC SHAFT

The static shaft of the mag drive centrifugal pumps HTM is made of alumina (Al2O3), an extremely robust ceramic material that ensures great stability and resistance to most hazardous liquids.

7.MAGNETS

The HTM pumps series are equipped with a high magnetic coupling created with magnets made of NdFeB. Thanks to this particular feature, the internal and external magnets won’t detach from each other while the pump is operating.