GemmeCotti srl has been designing and manufacturing chemical pumps for acids and dangerous liquids since 1992, when its founders started their own company after considerable experience in pump design and production.

Over the years, GemmeCotti has created its own range of industrial pumps designed and manufactured by its experienced team of experts. We are now specialized in magnetic drive pumps, mechanical seal pumps and vertical pumps.

The company is characterized by the high quality of its pumps, which is guaranteed by the use of materials of Italian origin and by the constant care of qualified and always up-to-date personnel, who pays special attention to the customer’s needs and offers assistance during the whole purchasing process.

About us

Our wide range of products includes magnetic drive centrifugal pumps, mag-drive turbine pumps, mag-drive vane pumps, vertical pumps, mechanical seal pumps and manufactured in thermoplastic materials (PP or PVDF) or metallic materials (AISI 316). All GemmeCotti pumps are in compliance with the Machinery Directive (CE/2006/42).

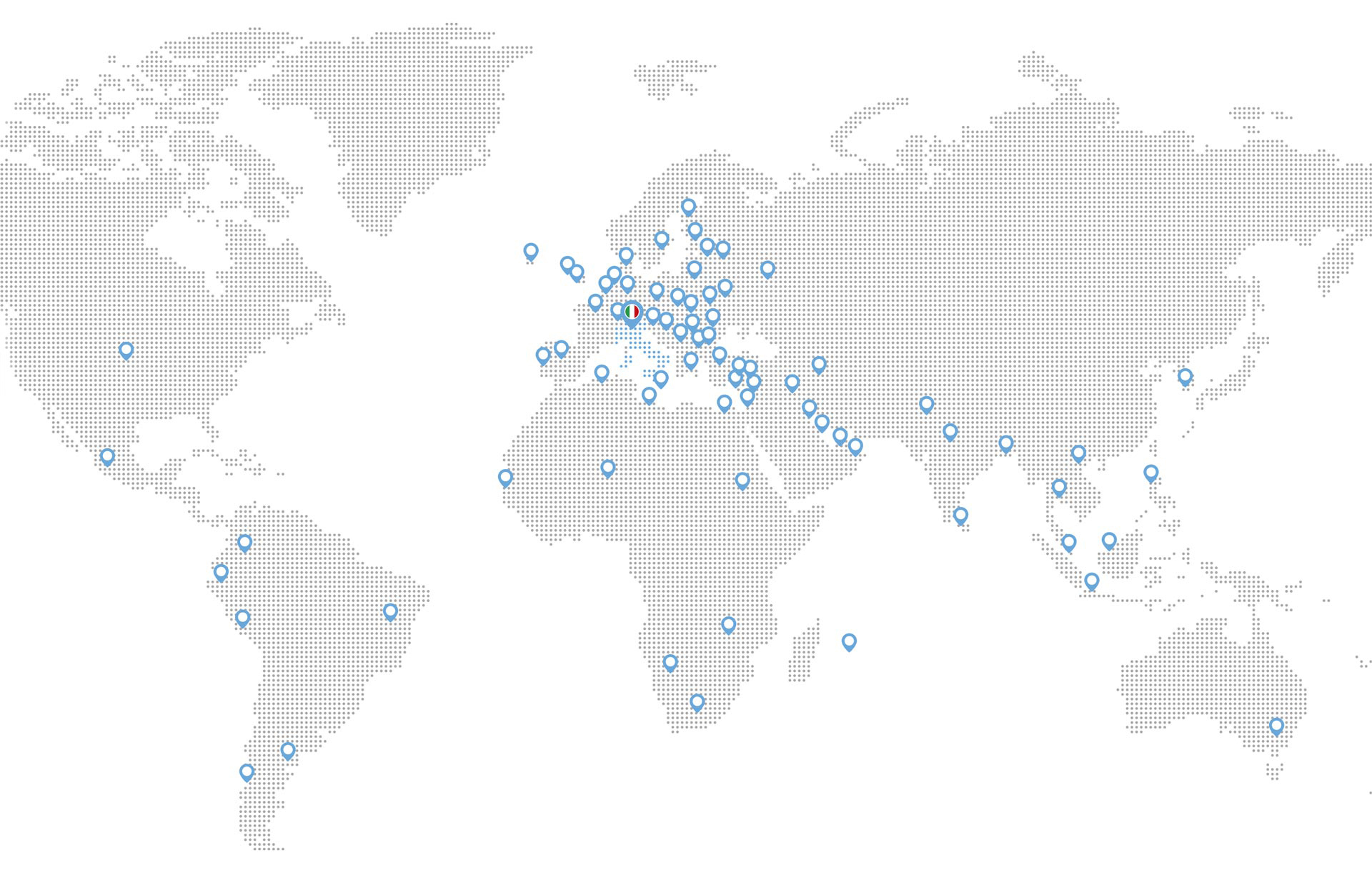

GemmeCotti pumps are valued worldwide and they are successfully used in many different industries including: chemical and petrochemical, pharmaceutical, oil refinery, electroplating, printed circuits, electronic, photography, military, water treatments, biotechnology, paper mills, textile, sugar plants, food processing, dairies and many others.

Armek Srl is an international subsidiary of the Italian company GemmeCotti Srl. Since 1992 Armek has been designing and manufacturing high quality magnetic sealless centrifugal pumps, magnetic sealless turbine pumps, magnetic sealless vane pumps and mechanical seal pumps suitable to pump acids and dangerous chemicals.

Gemme Plast is a company part of the GemmeCotti Group specialized in the injection moulding of plastic materials. We use high-performance polymers, including fluoropolymers, to manufacture technical parts for several sectors such as: mechanical engineering industries, automotive, household appliances, chemical and pharmaceutical industries, military and electronics industries. We plasticize your ideas: at Gemme Plast we follow our customers step by step, from the design to the injection moulding

Services

In addition to high-quality pumps, our company offers to customers further services.

The quick delivery of the ordered pumps is clear proof of the effectiveness of the production, but GemmeCotti also guarantees post-sales technical assistance with pump repair and spare-part supply even after the standard warranty period.

Values

The values that have guided the company from the beginning are: the quality of the pumps and of their materials, the competence, availability and courtesy of the employees who meet the customer’s needs and the constant desire to offer the best service in terms of price/quality and delivery time of the pumps.

Pump design

GemmeCotti’s technical office and research & development department are continuously involved in the design of new pumps and the improvement of the existing ones. Using CAD softwares we make 3D drawings of all the pump parts and pump assembly and then we use finite element method FEM to perform structure analysis in order to assure structural resistance and strength.

All the pumps are designed following four main objectives: have a reliable high-tech design, work and withstand the hardest conditions, be chemically resistant and suitable to operate with corrosive and aggressive liquids, guarantee a long-lasting service with minimum maintenance.

Our engineers are constantly involved in new projects and in the design of new pumps according to what the market of chemical pumps requires and to the customers’ needs. We are able to offer more than 500 pump variations for meeting a wide range of applications but, if requested, we can also customize our standard pumps according to the customer’s preferences.