APPLICATION: INSTALLATION OF CHEMICAL PUMPS IN SCRUBBER PLANTS

The emission of gasses in the atmosphere is regulated by specific national and international laws that must be respected by all industries. The term “air treatment” refers to systems and techniques used by the industries to keep the air quality and the level of pollution under control.

Scrubbers are the easiest and most efficient systems for purifying the air by removing particulates and/or gasses.

There are several types of scrubbers which are used in different industrial sectors.

FLUIDS GENERALLY INVOLVED IN THIS APPLICATION:

Scrubbers are generally used to:

- wash fumes (e.g. emitted by boilers or furnaces) with soda or other liquids, in order to remove hydrogen sulfide, hydrochloric acid, hydrocarbons and sulfur dioxide.

- depurate gasses (e.g. washing synthetic gasses with monoethanolamine in order to remove CO2).

Scrubbers are generally used by:

- petrochemical industries

- chemical and pharmaceutical industries

- galvanic industries

- packaging industries

- food industries

- cellulose industries

INDUSTRIAL PUMPS INSTALLED IN AIR TREATMENT AND FUME DEPURATION SYSTEMS

The polluted air is directed inside a chamber where it comes into contact with the washing liquid which transfers the pollutants from the air to the water. The purified air is released into the atmosphere while the polluting particles become an integral part of the washing liquid, which is then collected in a tank.

During this process, the polluted air goes from the bottom to the top while the washing liquid is pushed up by the use of centrifugal pumps and then it goes from the top to the bottom through the scrubber. The washing liquid collected in the tank is then recirculated by means of horizontal centrifugal pumps installed on the ground or through vertical pumps installed directly inside the tank. The pump continues to recirculate the same liquid which, after the transfer through the scrubber, returns to the tank.

SPECIFIC REQUIREMENTS FOR THIS APPLICATION: WHICH ARE THE BEST PUMPS FOR AIR TREATMENT AND FUMES DEPURATION SYSTEMS?

Additives inside the washing liquid are often hazardous chemical agents. For this reason it is necessary to use anti-corrosion pumps.

The pump used in this process can be installed next to the tank or vertically immersed in it.

In both cases, GemmeCotti offers suitable solutions:

Horizontal centrifugal pumps:

– series HTM PP/PVDF (magnetic driven)

– series HCO (mechanical sealed)

are the best solution for the installation next to the tank.

Vertical centrifugal pumps:

– series HV (monoblock)

– series HVL (with bracket)

are the ideal solution for installation with the pump immersed in the tank.

All these centrifugal pumps are made of thermoplastic materials PP or PVDF, which ensure a great chemical resistance to the chemical agents used in this application.

GEMMECOTTI CENTRIFUGAL PUMPS FOR THE AIR TREATMENT

MAGNETIC HORIZONTAL CENTRIFUGAL PUMPS SERIES HTM PP/PVDF

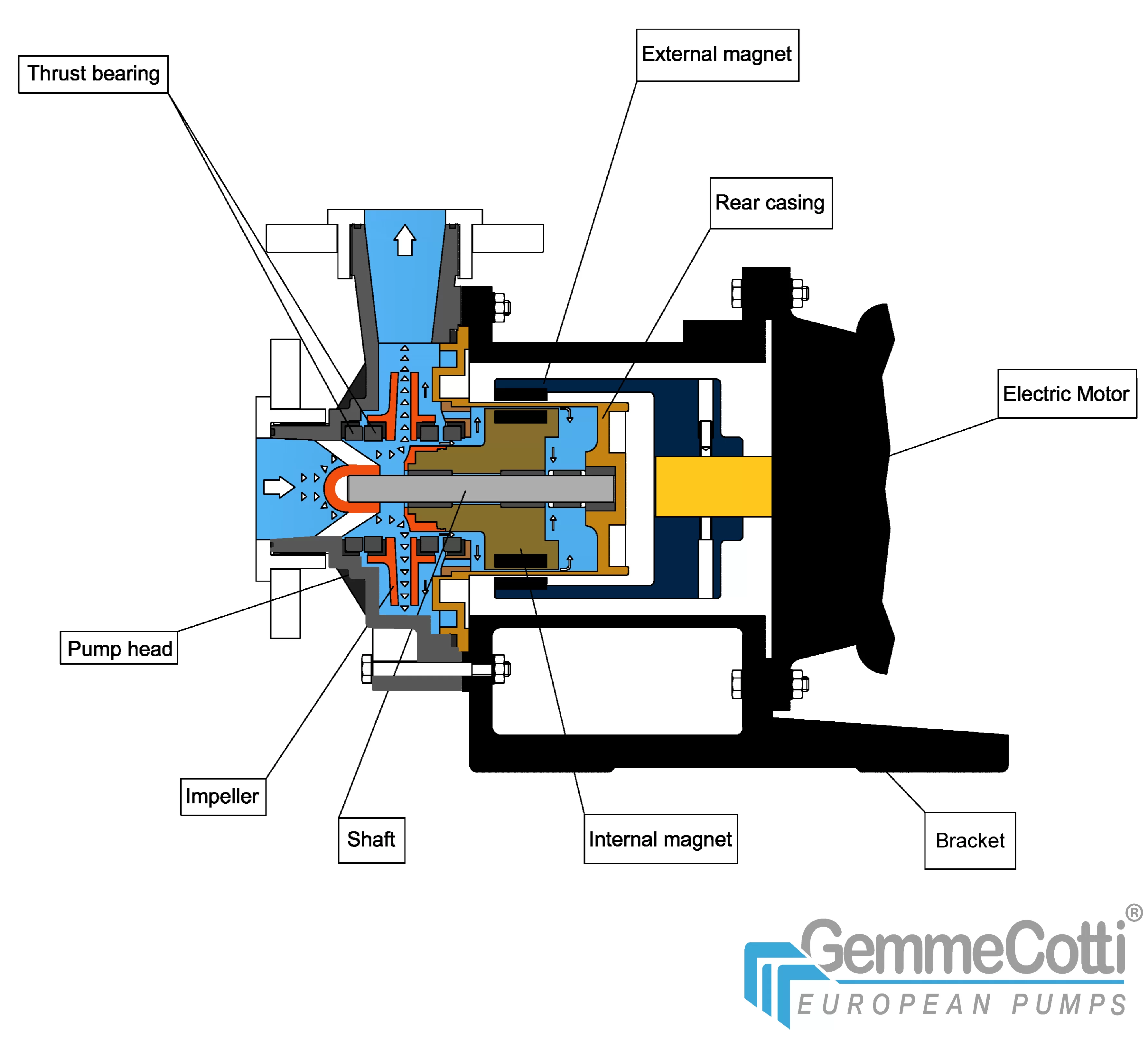

Mag drive pumps HTM PP/PVDF have a sealless design that is particularly suitable to pump corrosive and dangerous liquids; the magnetic design together with the usage of anticorrosive thermoplastic materials, ensures the high chemical resistance and the absence of leakage and emissions.

Technical data:

– Capacity up to 130 m3/h

– Head up to 48 mlc

HORIZONTAL CENTRIFUGAL MECHANICAL SEAL PUMPS SERIES HCO

Mechanical seal centrifugal pumps HCO are the best solution when the liquid has solids in suspension: their design with open impeller permits to transfer dirty liquids (non-abrasive solids – max. 5% – dimension max. 3 mm).

– Capacity up to 60 m3/h

– Head up to 38 mlc

VERTICAL CENTRIFUGAL PUMPS

Vertical centrifugal pumps are suitable for installations with the pump immersed directly in the tank.

VERTICAL CENTRIFUGAL MONOBLOCK PUMPS SERIES HV

Pumps series HV are available with different column lengths from 500 mm to 1000 mm.

Technical data:

– Capacity up to 40m3/h

– Head up to 22 mlc

VERTICAL CENTRIFUGAL PUMPS WITH BRACKET SERIES HVL

Pump series HVL are available with different column lengths from 500 mm to 2000mm.

– Capacity up to 57m3/h

– Head up to 39 mlc

Contact our commercial department, we will find together an interesting solution for your application: info@gemmecotti.com