One of the latest challenge of GemmeCotti technical department is the development of magnetic drive centrifugal pumps series HCM. These new pumps are designed with the innovative sealless mag-drive system and they are manufactured using thermoplastic materials highly resistant to corrosive liquids. We have already produced the two biggest sizes (HCM 100-80 and HCM 80-65) and we are about to expand the series with smaller pumps which can cover a wide range of performances.

The main features of HCM pumps are:

– flow rate up to 140 m3/h, head up to 50 mlc;

– manufactured using thermoplastic materials: PP (Polypropylene) or PVDF (Polyvinylidene difluoride);

– high quality materials in contact with the liquid: casing, impeller: PP/PVDF, o-ring: EPDM/VITON, shaft and ring: pure alumina 99,7%, bushings: PTFEC

– heavy walled casing machined from a solid block which guarantees a very high resistance to internal and external corrosion;

– integral flanged connections which ensure a zero leakage;

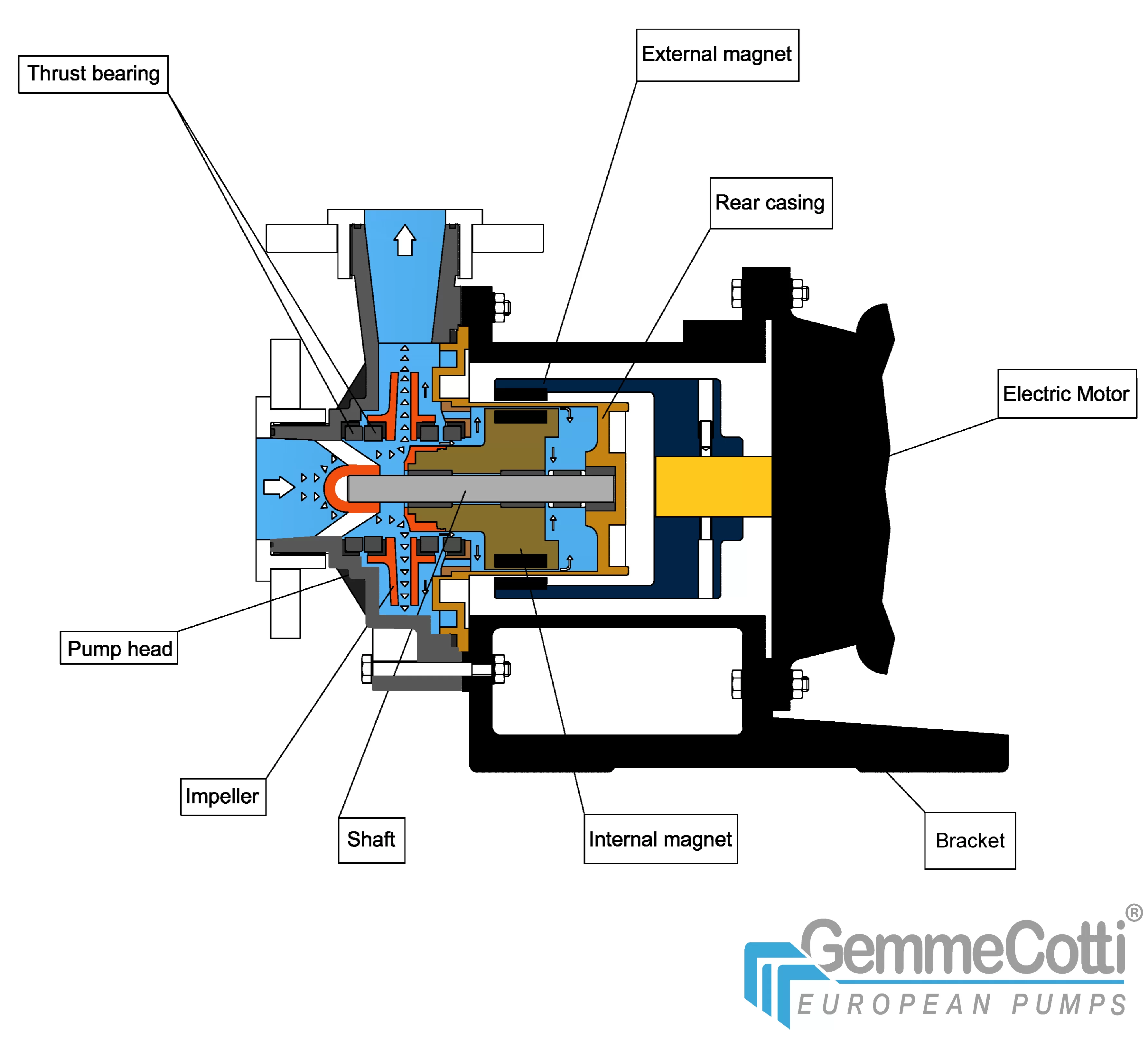

– the transmission of the motion occurs through magnetic joints without using mechanical seals. The synchronous magnetic coupling transmits torque from the external magnet connected to the electric motor, through a static rear casing, to the driven internal magnet inside the pump. This solution is ideal for pumping acids and dangerous liquids because it assures zero leakage of liquid or emissions;

These pumps are mainly used for severe applications where it’s necessary to transfer high corrosive liquids, like for example sulfuric acid, sodium hydroxide, sodium hypochlorite, brominated, chlorinated and fluorinated solutions.

We have already started to promote these new pumps to our customers and their response is helping us to proceed with the design of the entire series according to their needs and precious advices. We are now ready to start the mass production and we will keep you posted about further future developments.