If you need to select a chemical pump, first of all you should find out some important technical data which are extremely useful for the right choice of pump: capacity/flow and head/differential pressure required, kind of liquid, temperature, viscosity, possible presence of solids in suspension and if possible also NPSHa.

The performances required

Once you know the capacity (measured in m3/h- l/h- l/min – l/s) and the head required (measured in meters- mlc – bar) you should look at the performance curves of our pumps and see which series is the most suitable for the application. For example centrifugal pump series HTM are used for high capacities and medium head. On the contrary vane pumps series HTP are designed for low capacities and high pressure.

The pump material

Another important aspect to keep in consideration is the material of the pump (available materials: PP / PVDF/ AISI 316). It depends on the liquid to pump and its temperature. The material has to be chemically resistant to the fluid so chemical charts are really useful during this process. You can find an example of chemical chart in our website.

Presence of solids in the liquid

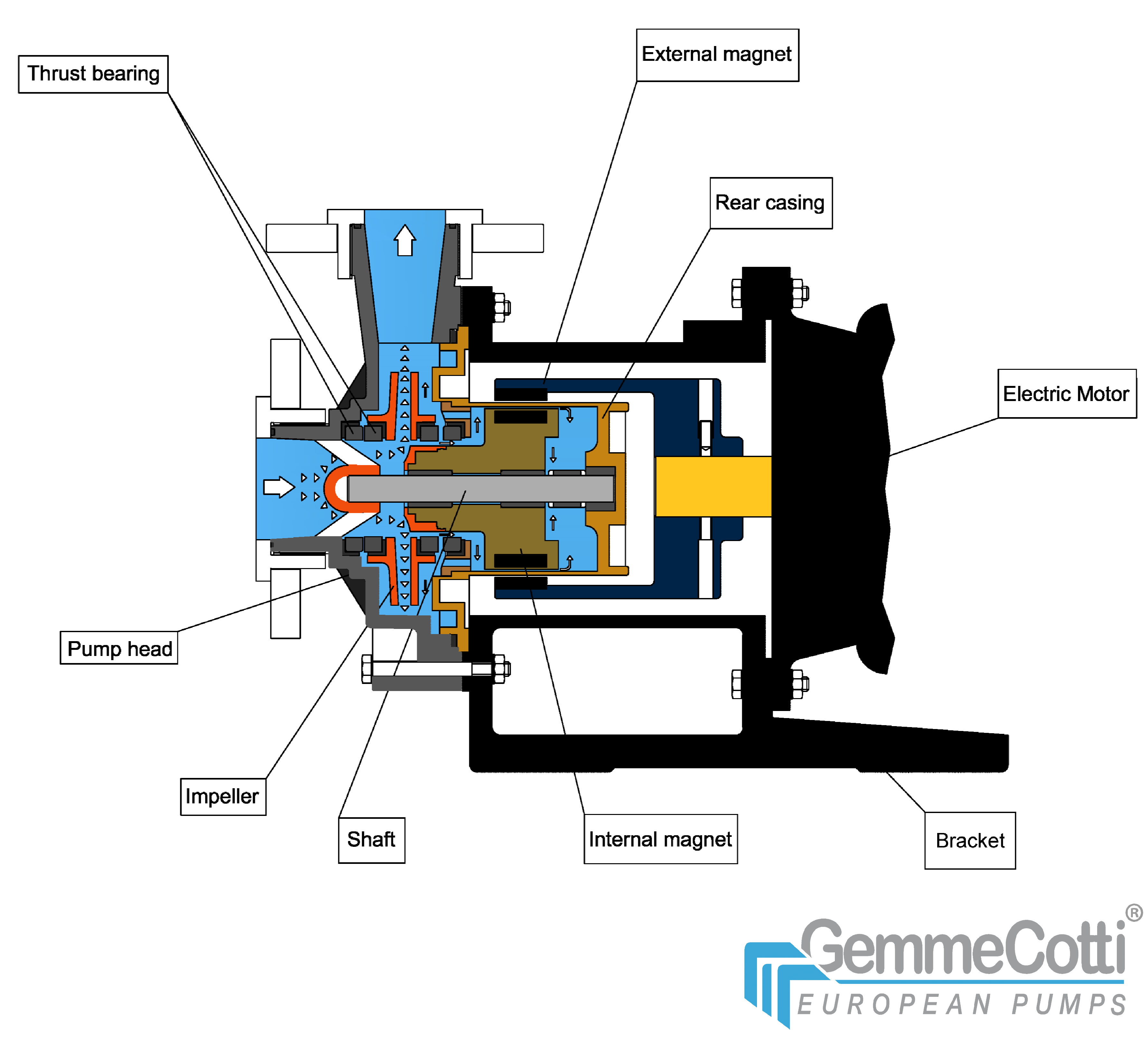

If the liquid is clean without solids in suspension, mag drive pumps such as for example HTM can be the right choice. Otherwise, if there are solid particles in the fluid you should use a mechanical seal pump, such as for example pumps mod. HCO.

NPSHavailable and NPSHrequired

The NPSHavailable (NPSHa) is important because it has to be higher than the NPSHrequired (NPSHr) that you can see on our curves to avoid cavitation into the pump and consequently its damage.

In case of any doubt regarding the pump selection you’d better contact the pump supplier who can help you to choose the suitable pump for your application. info@gemmecotti.com