Selecting an industrial pump for acids is a critical engineering decision that goes far beyond simply transporting fluids. A meticulous selection process is essential to ensure operational reliability, process efficiency, system longevity, and, above all, safety. Choosing the wrong pump can lead to premature failures, costly downtime, inefficient energy consumption, and potentially hazardous situations. This guide provides an analysis of the essential technical parameters to consider when selecting the most suitable pump for your needs.

Part 1: fluid characteristics

The fluid itself dictates most of the pump selection criteria. Its physical and chemical properties will determine the appropriate materials of construction, the type of pump required, and the power needed to move it.

1.1 Chemical composition and corrosivity

The first step is to identify every chemical component of the fluid. This analysis is crucial for selecting materials that can withstand corrosion, degradation, and chemical attacks.

- Materials of construction: The choice between metals (e.g., Stainless Steel 316), thermoplastics (e.g., PP, PVDF), and elastomers (e.g., EPDM, FKM, FFKM) depends entirely on chemical compatibility.

- Purity requirements: Applications in sectors such as pharmaceuticals or food may require specific materials (e.g., FDA-compliant) to prevent fluid contamination.

GemmeCotti specializes in this field, offering a wide range of pumps for acids and hazardous liquids made from thermoplastic (PP and PVDF) and metallic (Stainless Steel 316) materials. To select the right material for the pump, GemmeCotti technicians rely on over 30 years of know-how in the chemical pump field and compatibility charts from authoritative sources. To get an idea of material compatibility with the most common liquids, you can refer to the chemical compatibility guide.

1.2 Fluid viscosity

Viscosity is a measure of a fluid’s resistance to flow. It is one of the most critical parameters affecting pump selection and performance.

- Centrifugal pumps: These are highly efficient for low-viscosity fluids (e.g., water, solvents). However, as viscosity increases, their efficiency drops sharply, and the required motor power rises drastically. Generally, they are not suitable for viscosities above 200 cSt.

- Positive displacement pumps: These are the preferred choice for viscous liquids (e.g., oils, resins, syrups). They effectively handle higher viscosities, and their flow rate is less affected by viscosity changes.

- Turbine pumps: This type of pump provides a higher head than centrifugal pumps but can only handle low-viscosity liquids (max 45 cPs).

1.3 Fluid temperature

Temperature affects several parameters:

- Vapor pressure: Higher temperatures increase a liquid’s vapor pressure, which directly reduces the available NPSH (NPSHa). This increases the risk of cavitation.

- Viscosity: The viscosity of most liquids decreases as temperature increases.

- Material limits: Every material has a maximum operating temperature. Exceeding this limit can lead to mechanical failure.

1.4 Specific gravity (SG)

Specific gravity is the ratio of a fluid’s density to the density of water. It does not affect the head a centrifugal pump can produce (expressed in meters), but it directly impacts the pressure generated and the power required.

- Pressure calculation: Pressure (bar) = (Head (m) * SG) / 10.2

- Power calculation: The power required by the motor is directly proportional to the fluid’s specific gravity. A fluid with an SG of 1.5 will require 50% more power to be pumped than water, given the same flow rate and head.

GemmeCotti pumps are designed to accommodate different motor powers for the same pump size, allowing them to operate without issues of absorbed power even with high specific gravity liquids.

1.5 Presence and nature of solids

If the fluid contains suspended solids, it is necessary to define:

- Concentration: The percentage of solids by weight.

- Particle size, hardness, and shape: Abrasive solids (like sand or metal fines) require hardened materials and specialized pump designs (e.g., slurry pumps with vortex impellers or thick rubber linings) to resist wear. Soft or stringy solids can clog standard impellers, requiring a design specific to the application.

Part 2: System hydraulics – defining the workload

Once the fluid is understood, the next step is to define the system’s hydraulic requirements.

2.1 Required flow rate

This is the volume of fluid that needs to be moved in a given period, typically measured in m³/h, GPM (gallons per minute), or l/s. It is determined by the process needs.

2.2 Head and pressure

To move the fluid through the system, the pump must supply it with energy. This energy is commonly expressed as head. Head is the height to which the pump can push the fluid and is measured in meters of liquid column (m.l.c.) or simply in meters (m).

A fundamental aspect of head is that it is independent of the fluid type: the same pump will lift different liquids, even with different specific gravities, to the same height.

Pressure, on the other hand, is strictly dependent on the fluid’s density. At the same height (head), a column of liquid will exert a different force depending on its specific gravity. Consequently, a pump that generates a certain head will produce different pressures depending on the liquid it is pumping. For example, the pressure generated when pumping water will be different from that generated when pumping oil at the same head.

2.3 Net Positive Suction Head (NPSH)

As detailed in our previous article, a rigorous NPSH analysis is mandatory. You must ensure that your system’s NPSH available (NPSHa) is always greater than the pump’s NPSH required (NPSHr) to prevent destructive cavitation.

To further explore the difference between these two concepts, we have written a dedicated article on this topic: Pump Pressure vs. Head.

Part 3: Environmental and operational factors

The final set of parameters concerns the pump’s installation environment and intended use.

3.1 Installation area (ATEX)

For hazardous environments where flammable gases, vapors, or dust may be present, a pump certified for that specific ATEX zone is legally required to prevent ignition.

3.2 Environmental conditions

- Temperature and humidity: High ambient temperatures can affect motor cooling and performance. High humidity can lead to corrosion or problems with electronics.

- Altitude: At higher altitudes, the lower air density reduces the cooling effectiveness of standard fan-cooled motors, often requiring a motor derating.

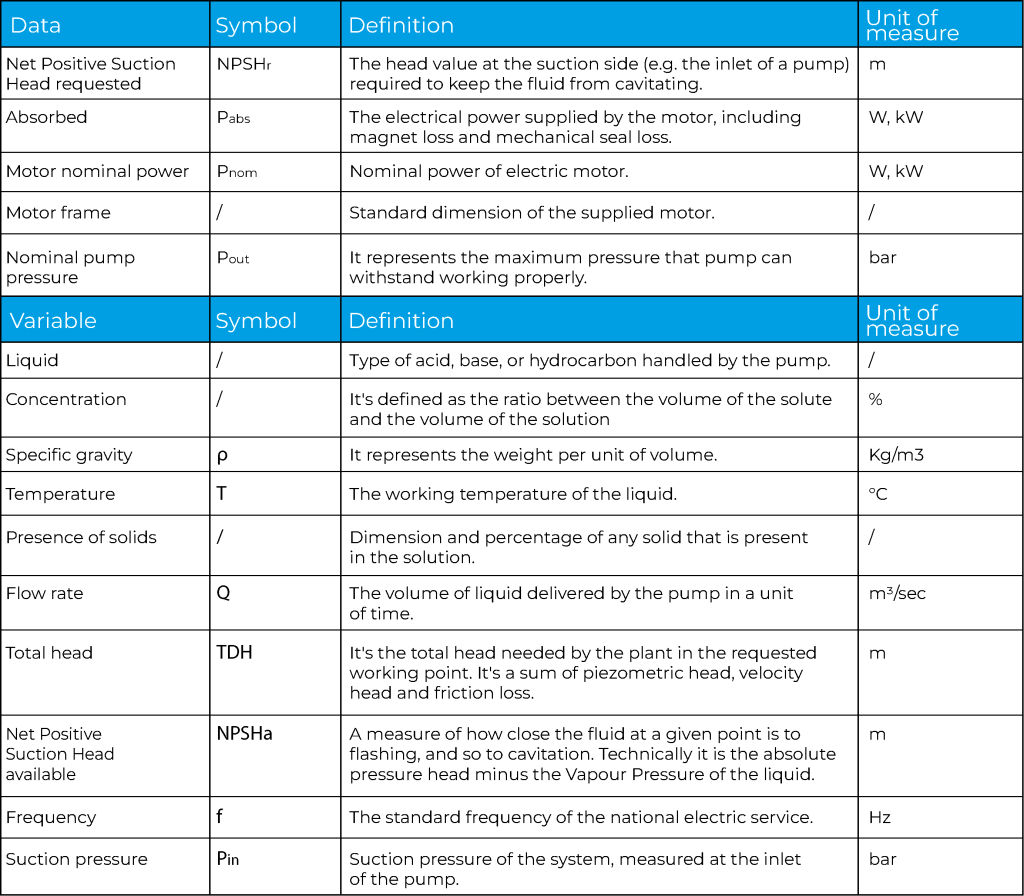

To summarize, all the essential parameters discussed are laid out in the following table. This provides a checklist of the data and variables required for a correct pump selection. It is crucial to accurately define these values to proceed with the identification of the most suitable pump.

Conclusion: A data-driven decision

The pump selection process is a meticulous engineering task that requires a thorough analysis of fluid properties, system hydraulics, and environmental conditions. By systematically evaluating each parameter—from chemical compatibility and viscosity to total dynamic head and ATEX requirements—you can ensure the selection of a pump that is not only effective but also highly reliable, energy-efficient, and safe. This data-driven approach goes beyond mere guesswork, guaranteeing a robust solution that will serve your process effectively for years to come.

For expert assistance in analyzing these complex parameters and selecting the ideal pump for your application, contact our team at info@gemmecotti.com.