As pump manufacturers, we daily face with a lot of inquiries that are often not complete because of the lack of data that are essential to let us quote the correct pump solution. In order to help our customer to get their way out of the jungle of the parameters, we have defined a table of the main variables that should be considered during the pump selection. This article would like to be a light vademecum to simplify the communication requesting for a quotation.

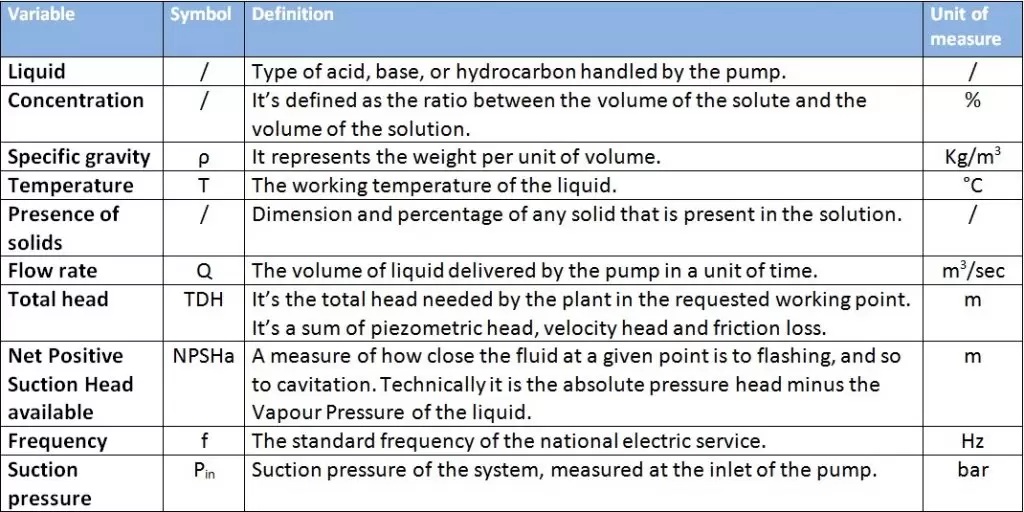

Variables of the pump selection

The following table includes the indispensable variables that our technicians have to know during the selection. We strongly recommend our customers to communicate the following data so that we can proceed with the selection.

Thanks to these references, our technical department will be able to select the best solution for every inquiry.

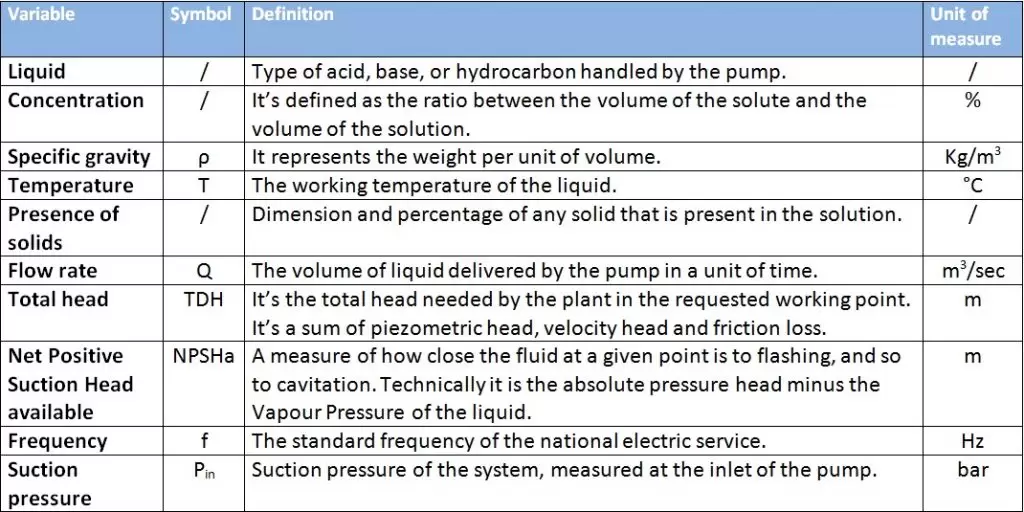

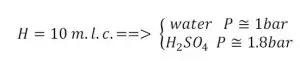

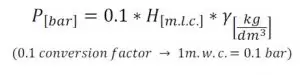

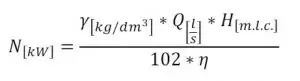

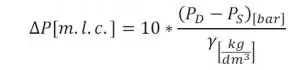

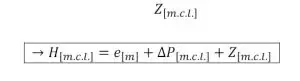

Moreover, once the selection is done, our technical department will provide the customers with some helpful derived parameters that are necessary for the plants.

Parameters confirmed by the pump technicians

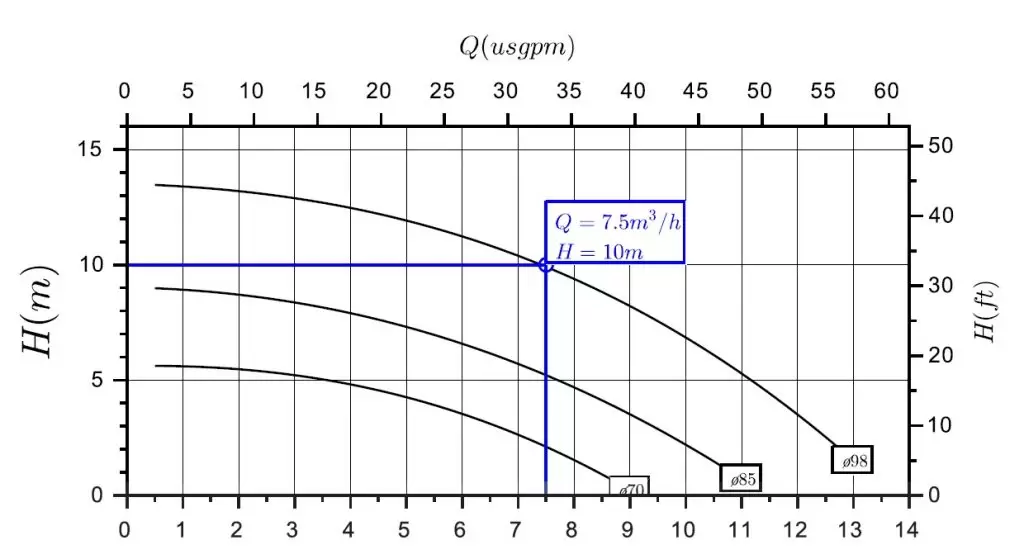

Indeed, after the selection, our technicians, first of all, confirm the actual head and flow that pump can reach and the diameter of the impeller. Then they give the customers the data shown in the table below. This information let our customer be able to technically evaluate our proposal according to the construction features of the plant.

Is it more clear now? Should you need any further information, please contact us at info@gemmecotti.com. We will be glad to dissipate all your doubts.

Don’t forget to save this post in your bookmarks, in order to easily recover it! And to select the right material for the pump, take a look also at our chemical compatibility guide.

References:

https://en.wikipedia.org/wiki/Net_positive_suction_head

https://web.archive.org/web/20170603124924/https://www.ksb.com/blob/333370/f0c49eb441d360b61f48f08ec47d78ab/pdf3-data.pdf