In the field of pumping corrosive and hazardous liquids, safety is not an option but an absolute necessity. Chemical fluid leaks can cause environmental damage, risks to operators, and costly downtime. The GemmeCotti HTM series was developed to meet these challenges, offering a zero-leak solution thanks to its magnetic drive design.

In this guide, we will explore how it works, its advantages, and how to choose the ideal configuration of HTM centrifugal pumps for various industrial processes.

What is magnetic drive and how does it work?

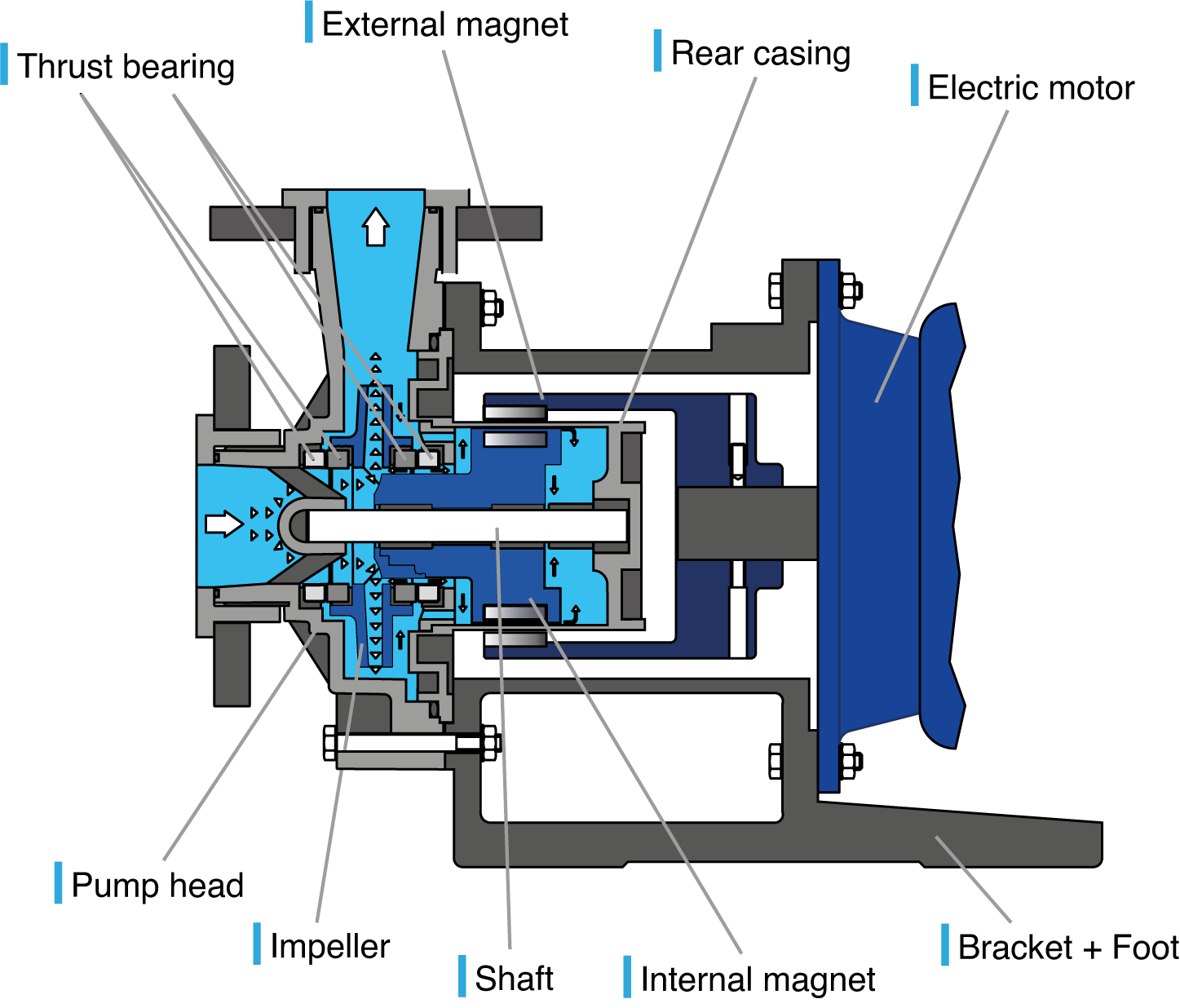

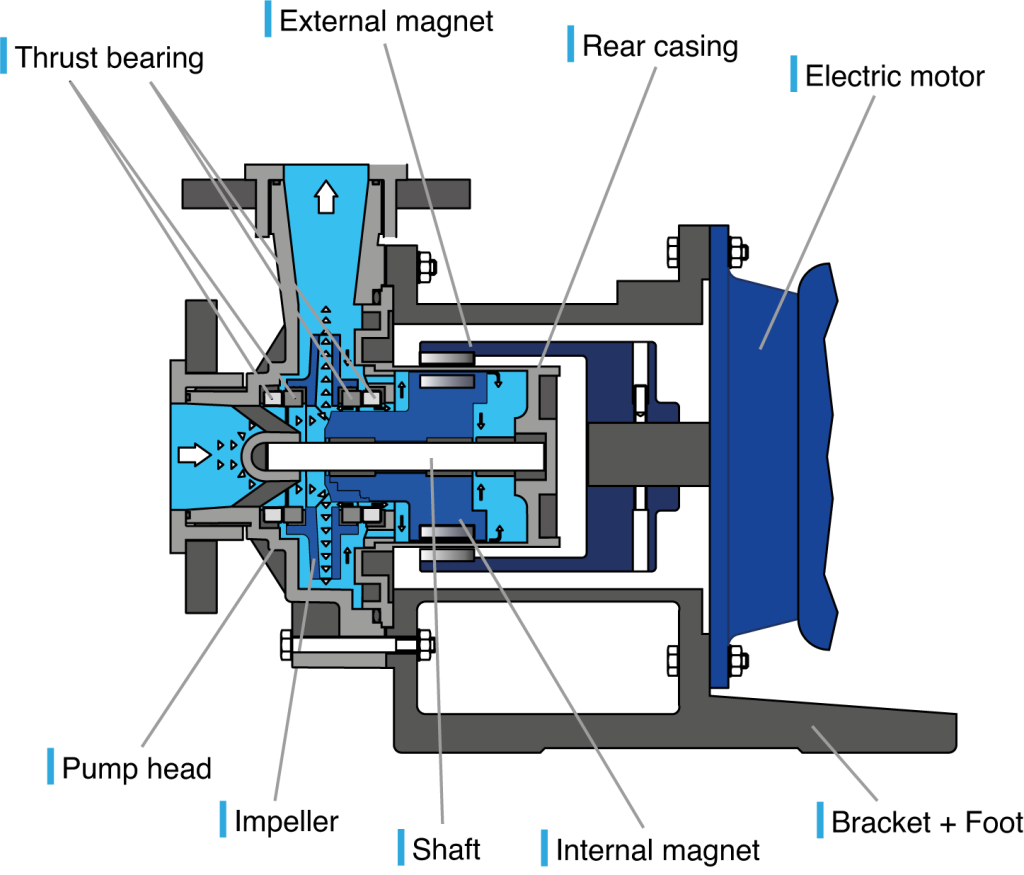

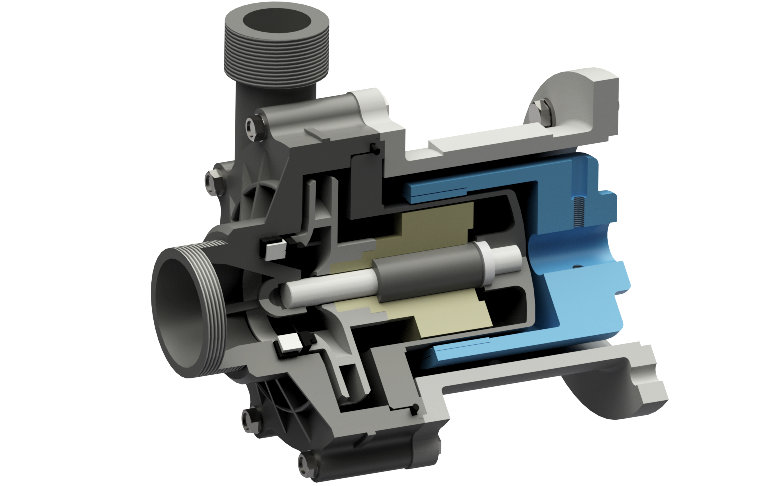

Unlike traditional pumps with mechanical seals, GemmeCotti HTM series pumps use an innovative design without a mechanical seal. In a magnetic drive pump, there are two magnetic couplings: the outer magnet, mounted on the motor shaft, and the inner magnet, which allows the impeller to rotate and move the fluid.

The two magnetic semicouplings are separated by a containment shell and never come into contact with each other; the inner magnet rotates exclusively through the magnetic field action. The liquid therefore always remains hermetically sealed within the hydraulic part of the pump. This design ensures maximum safety, greater reliability, and excellent efficiency, even in the most demanding applications.

For an even more detailed visual explanation, an explanatory video is available on YouTube showing the operating principle in action.

What are the advantages of HTM magnetic drive pumps?

Choosing a GemmeCotti magnetic drive pump means investing in safety, efficiency, and quality.

The advantages that distinguish these acid pumps are:

- No leaks or emissions: ideal for handling hazardous chemicals. The liquid always remains hermetically sealed inside the hydraulic section of the pump.

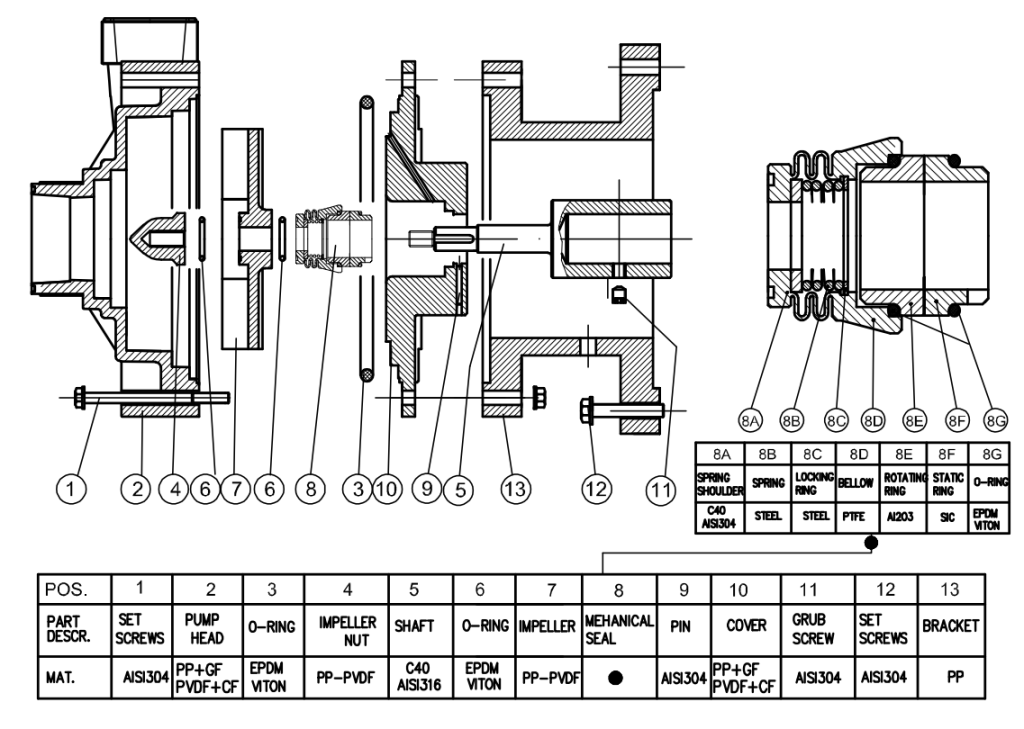

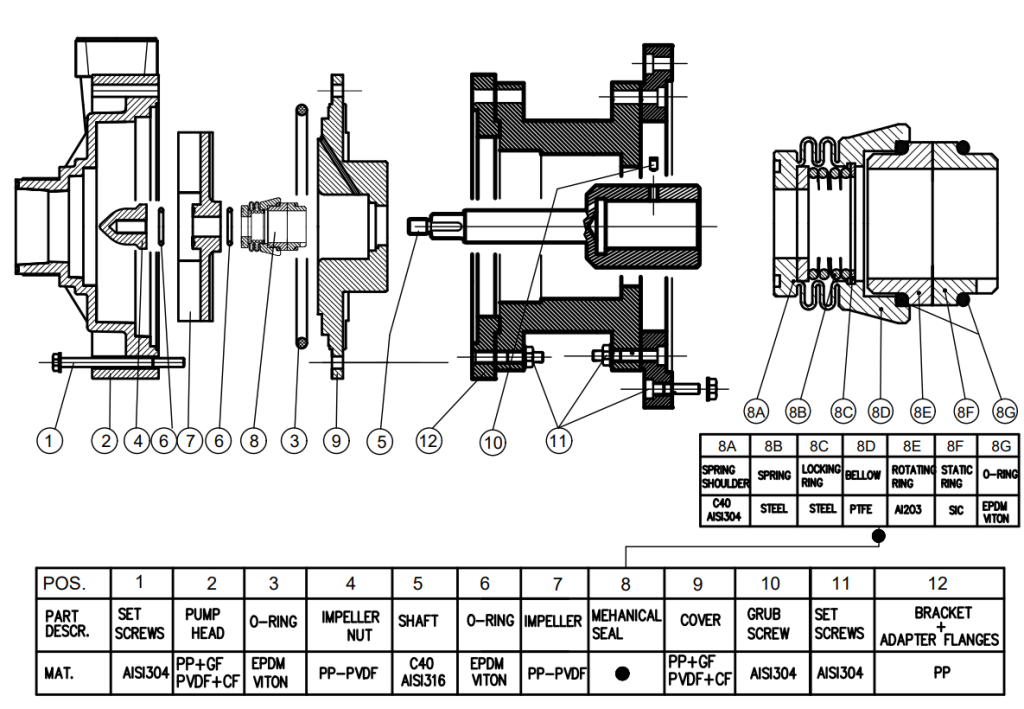

- Reduced maintenance: fewer wear components (such as mechanical seals) means lower operating costs, no plant downtime, and long-term savings.

- No motor/pump alignment required: the compact design simplifies installation and reduces vibrations.

- Maximum reliability: solid construction made of chemically resistant materials (PP, PVDF, AISI 316). HTM series centrifugal pumps are the ideal solution for long-lasting performance, even in heavy-duty conditions.

- Long-term savings: pumps designed to last for decades.

- High-torque magnetic coupling: these pumps are designed to ensure high torque of magnetic couplings.

Performance and materials: a tailor-made solution for every need

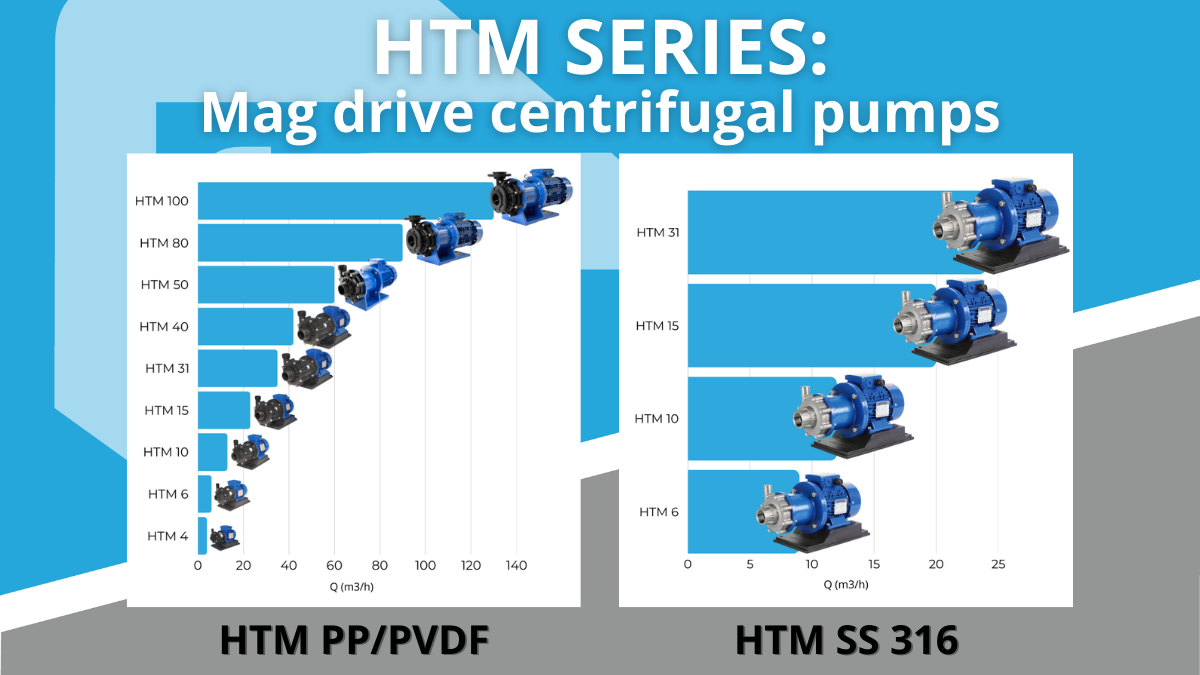

Every industrial application has different requirements. For this reason, the HTM range, from size 4 to 100, offers wide operational flexibility.

Technical specifications

- Flow rate: From 0.5 to 130 m³/h (2–528 USGPM)

- Head: Up to 48 meters (148 ft)

Chemical compatibility

The choice of material in contact with the liquid is essential for pump durability:

- PP (Polypropylene): Excellent for many liquids such as phosphoric acid, ammonia, and caustic soda.

- PVDF (Polyvinylidene Fluoride): Ideal for aggressive acids such as sulfuric acid, hydrofluoric acid, sodium hypochlorite, and many others.

- AISI 316: Stainless steel suitable for fluids such as diesel, acetone, ethyl alcohol, hydraulic oils, and many others.

In addition to thermoplastic versions, HTM pumps can also be manufactured in AISI 316 stainless steel. This configuration is particularly suitable for demanding industrial applications requiring high mechanical and thermal resistance. The robustness of steel, combined with the safety of magnetic drive technology, makes these pumps the ideal choice for transferring hydrocarbons and solvents with total absence of leaks.

Technical specifications (AISI 316 Version)

- Flow rate: From 0.8 to 32 m³/h (3–175 USGPM)

- Head: Up to 24 meters (110 ft)

Discover the complete range and specifications of HTM magnetic centrifugal pumps in AISI 316.

For explosive environments, ATEX Zone 1 and 2 versions are also available (Models EM-C PP/PVDF and EM-C AISI 316).

The GemmeCotti team is available to help customers select the pump best suited to their application.

Contact us at info@gemmecotti.com for a free quotation.

Sizes:

Sizes: