A good sales service for a chemical pump company does not depend only on how the sales office or the customer service interact with the client but many more factors plays an important role on the satisfaction of the customer. We can say that all the pump factory management has an impact on the sales process but one of the factors which has a direct impact on the customer is the warehouse management of pumps and spare parts.

Having an organized and well managed warehouse is the first step for a good service to the customer from the first quotation to the supply of spare parts for the pump maintenance. As a matter of fact, if the stock situation is clear it is possible to indicate in all the quotations precise delivery dates so that the customer can correctly schedule the pump installation. After plac ing order, the customer can be informed step by step about the status of the pumps, if the pumps are ready on stock or if the delivery can take some days. Moreover, it is essential to have the main spare parts always on stock in case of urgent orders of pumps or spare parts for maintenance and repair, in this way the customer can receive the products quickly and avoid useless long plant shutdowns.

ing order, the customer can be informed step by step about the status of the pumps, if the pumps are ready on stock or if the delivery can take some days. Moreover, it is essential to have the main spare parts always on stock in case of urgent orders of pumps or spare parts for maintenance and repair, in this way the customer can receive the products quickly and avoid useless long plant shutdowns.

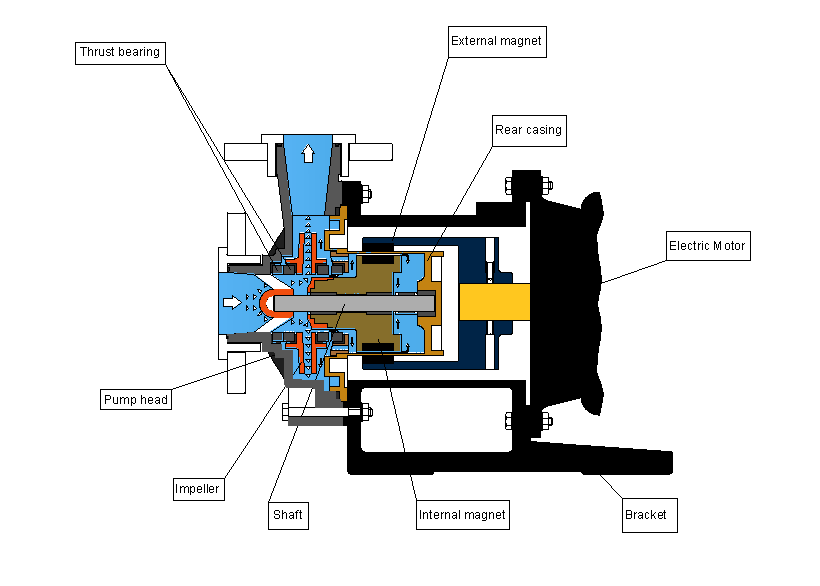

GemmeCotti pays great attention to the aspect of the warehouse management but many companies ignore this part because it is considered a waste of time. This choice can seem true on a short period of time, but in the long run there will be many problems with consequent bigger waste of time to solve issues caused by a poor management. If a company wants to develop, the warehouse management is really important because, in addition to the positive aspects for the customer, it avoids excessive capital being tied up, optimization of the available space and on the long run a cost reduction.

First of all it is necessary to codify all the parts and keep tracks of the quantities. Then the parts should be rationally organized to make the management more rapid and effective, in addition to the obvious space optimization and cleanliness.

Once the warehouse is well organized it is also very important to keep the everything in order. To do so, a software can help the management of the stock but it is important to choose the right software in accordance with the real needs of the company in order to get more benefits.

The warehouse management in GemmeCotti has recently being checked and improved for an even better service to the customer and a bigger pumps availability on stock. If the customer is in urgent need for a chemical pump, we are ready to satisfy him in no time.