HTT-SP pumps can prime up to 5 m with water at ambient temperature. The casing is made from a PP solid machined block and the impeller in PVDF for maximum chemical resistance. The casing is machined from a solid block. The impeller in PVDF is self-balanced to eliminate thrust bearing wear and it is separate to minimize the maintenance costs. This kind of pump offers maximum resistance with standing also external corrosion. It handles up to 20% entrained gas and resists cavitation.

HTT-SP – SELF-PRIMING MAG DRIVE REGENERATIVE TURBINE PUMPS

HTT-SP – SELF-PRIMING MAG DRIVE REGENERATIVE TURBINE PUMPS

Magnetic drive regenerative turbine pumps made in thermoplastic materials

Anti-corrosion industrial pumps suitable for pumping acids and bases fluids and highly corrosive liquids

- Materials available: PP or PVDF;

- Materials in contact with the liquid:

Pump housing: PPor PVDF;

Impeller: PVDF;

O-ring: EPDM (standard for PP pumps) /

VITON (standard for PVDF pumps);

Static shaft: Al2O3 99.7%;

Bearing: PTFEC. - Max flow: 6 m3/h; max head 28 mlc.

- Max temperature: PP: 70°C – PVDF: 90°C.

- High torque magnetic coupling.

- Chemical resistant PTFE/carbon sleeve bearings.

- Static shaft in high purity ceramic.

- Direct starting motor.

- Available in ATEX version for zone 2 I I 3G (pump mod. EM-T SP)

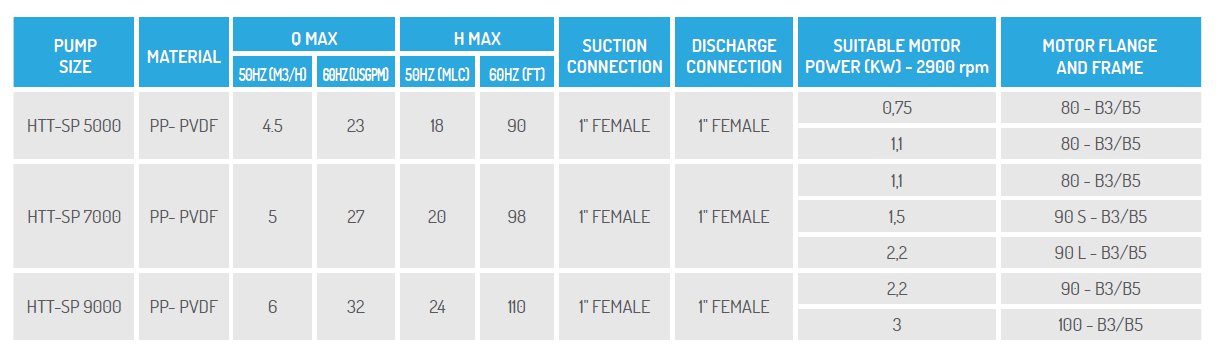

TECHNICAL DATA

* The head and flow of the pump refer to the performance with water at room temperature. Should liquids at high temperatures and with high viscosity and density be pumped the performance has to be calculated accordingly. The electric motor should be selected on the basis of the viscosity and the specific weight given by the customer.

*For any information and quotation you can fill in the online form or send an email to info@gemmecotti.com. Our commercial office will select the pump suitable for your needs.

STRONG POINTS OF HTT-SP PUMPS

MANUFACTURING MATERIALS

HTT-SP pumps are made of thermoplastic materials PP o PVDF and they are compatible with most acids and basic liquids, chemicals and other dangerous fluids.

LEAK FREE MAGNETIC DESIGN

Advantages of magnetic drive pumps:

– no mechanical seal

– no leakage and emissions

– no motor/pump alignment

– environmental sustainability

– reliability and safety

– limited periodic maintenance with long-term savings

RELIABILITY

Unlike many centrifugal pumps on the market the pump head of GemmeCotti pumps is fixed to the bracket with 8 bolts. This feature guarantees a firm fastening of the pump head to the bracket and avoid the casing deformation under pressure.

SELF-PRIMING ABILITY

HTT-SP pumps can prime up to 5 m at sea level liquids with specific gravity 1 and at room temperature.

STATIC SHAFT

The static shaft of the mag drive turbine pumps HTT-SP series are made of Alumina 99,7% (Al2O3), an extremely resistant ceramic material, which guarantees the maximum stability and resistance to aggressive chemicals.

MAGNETS

The HTT-SP pumps are equipped with NdFeB magnets that ensure a high magnetic torque

MACHINED CASING

HTT-SP series pump casing is machined from a solid block. This kind of pump offers maximum resistance withstanding also external corrosion.

MAGNETIC DRIVE DESIGN

Magnetic drive pumps are designed with a special sealless configuration that is suitable for handling acids, chemicals, corrosive and dangerous liquids thanks to the high chemical resistance of their construction materials and to the absence of leakage and emissions. The design is really simple and it requires very little maintenance with consequent cost savings in terms of repairing, spare parts and machine downtime (costs during the pump life). This type of pump is not suitable for transferring liquids with solids. Liquid must necessarily be clean and free of suspended solids (max presence of solid admitted: max 2% – max 1mm).

Discover more about magnetic drive pumps

OPTIONAL

FLANGES

On request GemmeCotti provides DIN e ANSI flanges for thermoplastic pumps (flat stub + slip-on flanges) and welded DIN o ANSI flanges for pumps in AISI 316.

BASEPLATES

GemmeCotti baseplates are suitable for pump completed with motor with B3/B5 configuration. They allow the correct positioning of the pump.

A1-13Y

We recommended the use of the dry-running protection device for all the applications where the constant presence of liquid in the pump is not always ensured.