Vertical mag drive centrifugal pumps series HTM-V are made of thermoplastic materials (Polypropylene and PVDF) and are suitable to handle chemicals and corrosive liquids. This kind of pump has been designed for a vertical submerged installation, providing high reliability for in tank and sump applications. HTM-V are sealless magnetic drive pumps without any kind of labyrinth or mechanical seal. The column of the pump is hermetically sealed and it allows complete isolation of the motor, the extension shaft and external magnet of the pump from the process liquid.

HTM-V – VERTICAL MAG DRIVE CENTRIFUGAL PUMPS

HTM-V – VERTICAL MAG DRIVE CENTRIFUGAL PUMPS

Vertical self-priming magnetic drive centrifugal pumps made in thermoplastic materials

Anti-corrosion industrial pumps suitable for pumping acids and bases fluids and highly corrosive liquids

- Materials available: PP /PVDF.

- Materials in contact with the liquid:

casing and impeller: PP/PVDF;

o-ring: EPDM (standard for PP pumps);

VITON (standard for PVDF pumps);

shaft: Al2O3 99,7%; bushing: PTFEC. - Max flow: 22 m3/h. Max head 20 mlc.

- Temperature: PP: max 70°C – PVDF: max 90°C.

- Compact design, column length 320mm.

TECHNICAL DATA

* The head and flow of the pump refer to the performance with water at room temperature. Should liquids at high temperatures and with high viscosity and density be pumped the performance has to be calculated accordingly. The electric motor should be selected on the basis of the viscosity and the specific weight given by the customer.

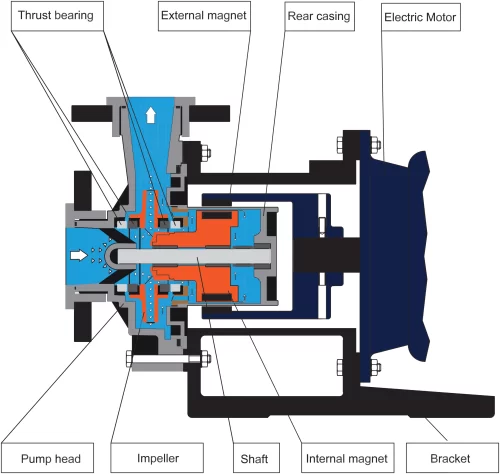

MAGNETIC DRIVE DESIGN

Magnetic drive pumps are designed with a special sealless configuration that is suitable for handling acids, chemicals, corrosive and dangerous liquids thanks to the high chemical resistance of their construction materials and to the absence of leakage and emissions. The design is really simple and it requires very little maintenance with consequent cost savings in terms of repairing, spare parts and machine downtime (costs during the pump life). This type of pump is not suitable for transferring liquids with solids. Liquid must necessarily be clean and free of suspended solids (max presence of solid admitted: max 2% – max 1mm).

Discover more about magnetic drive pumps