For more than 20 years we have been pursuing one main goal: design and produce magnetic pumps which meet the customers’ needs. That’s what drives us and makes us world-leader in the field of chemical pumps. So what are the characteristics of GemmeCotti pumps which make them unique and so appreciated by customers the world over?

1- Wide range of pumps among which the customer can choose. We have more than 400 pump variations so that we can always offer to the customer the right solution for his application. Each pump is customized according to many variables:

- 6 different pump designs: mag drive centrifugal pumps, mag drive turbine pumps, mag drive vane pumps, mechanical seal pumps, liquid ring vacuum pumps, vertical pumps

- 3 different materials suitable to pump acids and chemicals: PP (polypropylene), PVDF, AISI316

- several o-ring variations

- many accessories (flanges, baseplates etc.)

2- High quality pump materials. It’s important for us to offer the highest quality possible that’s why we choose only the best materials (Polypropylene, PVDF and AISI316) which can resist corrosion and which are suitable to pump almost every existing chemical. You can check out our chemical compatibility chart for more information and to select the right pump material for your application.

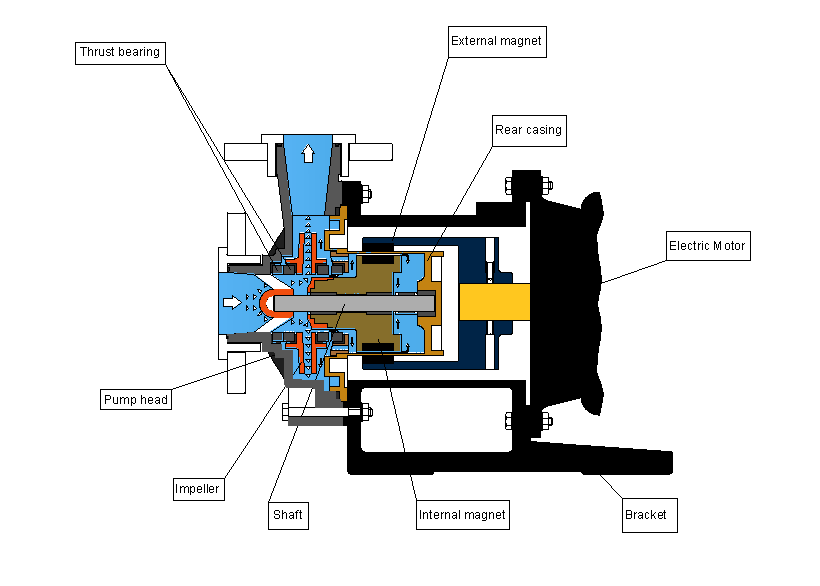

3- Best pump design for pumping chemicals. Magnetic drive pumps have a simple sealless design which is the ideal solution when handling chemicals and acids. The hydraulic part of the pump is hermetically closed so there is absolutely no leakage and emission of fluid. This is an essential characteristic because mag drive pumps guarantee safety for both workmen and the environment. Moreover the absence of any seal makes the pump highly reliable eliminating the maintenance and repair costs.

Typical pump design: The external magnet of the pump is placed on the motor shaft and when rotating it transmits the motion to the internal magnet thanks to the magnetic attraction of the two joints. The internal magnet is connected to the impeller which spins and moves the fluid through the pump. The external magnet and inner magnet are separated by a rear casing that creates a hermetic containment of the liquid that has no access to the outside.

4- Chemical pumps completely Made in Italy. We are an Italian manufacturer and we are proud to offer high quality pumps designed, assembled and tested directly in our workshop. The pump parts are made and machined by our Italian suppliers all located near our factory. So, for us, suppliers play an important role in the resulting quality of the pumps. That’s why we choose and qualify them through a strict qualification process and we keep a close relationship with everyone in order to assure the highest quality of each pump part and consequently of the complete chemical pump assembly.

5- Every pump is checked and tested before delivery. What is the best way to assure the pump quality than try it personally? We perform rigorous tests during the whole assembly process according to ISO9001 based quality control standards. That is not all. We want to achieve zero defect rate, which is why we test every single pump at our test bench before delivery to our customer to check both the performances and the correct functioning.

6- Chemical pumps suitable for many applications. GemmeCotti industrial pumps can be used in various applications where chemicals, acids, dangerous liquids are involved, such as: chemical industries, waste water treatments, galvanic industries, surface treatments (zinc-plating, silver-plating, coppering galvanic treatments, chemical nickel plating) in machines and equipment for the printing industry, in machines for tanning industries, for printed circuit boards production, in scrubbers, air treatment plants, petrochemical and oil & gas industry, for biofuel handling, in textile industry, food industry and in bottling machines. Moreover GemmeCotti mag drive pumps can be used also for pumping salty water and water containing detergents.

Contact our sales department and we will help you choose the right pump for your application.