To safeguard magnetic drive pumps against damage caused by insufficient liquid, GemmeCotti offers the Emirel A1-13-Y dry-running protection device. Specifically designed for these pumps, this device prevents dry running, closed discharge, and blocked suction scenarios. Its adjustable threshold and timer allow for customization of minimum power and operational time settings. If power falls below the set value, the pump is automatically stopped, ensuring protection. This device is especially valuable during tanker unloading operations and in any application where liquid shortage poses a risk.

Main features

- Single Phase CURRENT RELAY

- Multirange 15-35A

- 2 set points MAX / min

- Also for motors with INVERTER

- Direct insertion TA through

- LCD Display

What happens when a pump runs dry?

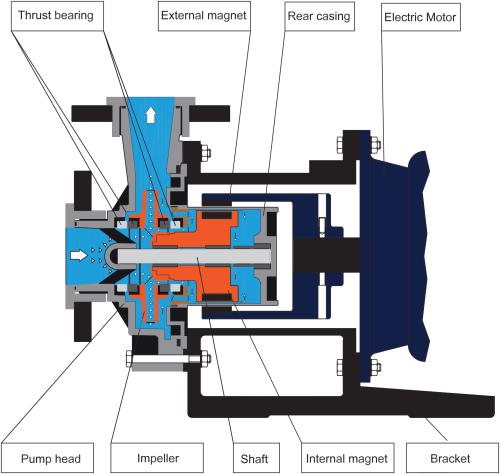

When a pump works without fluid there is a sudden increase of the internal temperature with destructive results of some pump parts. For example, when a plastic pump (in PP or PVDF) runs dry, the main damage occurring are:

1- the shaft in ceramic may break due to a thermal shock.

2- the rotating bushing may block on the shaft.

3- melting of some plastic parts (impeller, rear casing, internal magnet etc.) due to the sudden temperature rise.

How is it possible to prevent dry running?

To avoid the inconvenience of the dry running you can simply install a dry running protection device which stops the pump immediately in case of danger of dry-running. As a matter of fact, the device checks constantly the active power of the motor, which is the minimum value of the instantaneous power absorbed by the pump, through the reception of information about the voltage, the cosφ and current variations. Through a set point and a timer, which are adjustable, it’s possible to set the minimum power and the triggering time of the device. If the power goes under the established value, the pump stops and the device must be switched on again manually. In case of continuous intervention on the apparatus, check the presence of liquid and/or the correct functioning of the plant to find the cause of working of the device.

Click here to find out more.