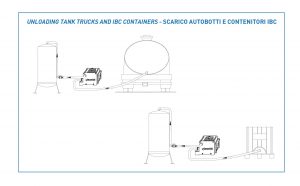

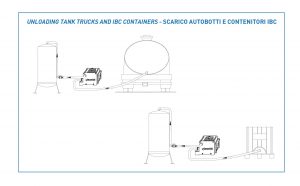

APPLICATION: CHEMICAL PUMPS TO UNLOAD TANKER TRUCKS AND RAILROAD TANK CARS

GemmeCotti supplies industrial pumps suitable to unload railroad tank cars and tanker trucks containing acids and toxic chemicals.

We offer three possible solutions for this application:

- installation of one pump for each single tank

- installation of the pump directly aboard the vehicle (GemmeCotti series HTM or series HCO)

- use of the portable pump H-IBC (GemmeCotti series HTM 10)

SPECIFIC REQUIREMENTS FOR THIS APPLICATION: WHICH ARE THE BEST PUMPS FOR TANKERS OFFLOADING?

The right pumping solution for unloading and transferring dangerous liquids from vehicles (trucks or railroad tank cars) is selected according to the chemical compatibility and the requested performances.

GemmeCotti pumps are the best choice to transfer dangerous or hazardous goods, i.e. all the substances which, due to their peculiar properties, could be harmful for the environment or the people involved.

These liquids are classified according to their characteristics and degree of danger. In Europe, the transportation of toxic chemicals is regulated by specific laws:

- ADR: agreement concerning the international transport of dangerous goods by road

- RID: international carriage of dangerous goods by rail

- ADN: carriage of dangerous goods by inland waterways

GemmeCotti is proud to offer pumping solutions for the safe handling of chemicals: we supply chemical pumps suitable for the safe offloading of the great majority of dangerous or hazardous goods.

Fluids generally involved in this application:

- ammonia

- sulphuric acid

- nitric acid

- hydrochloric acid

- sodium hydroxide (caustic soda)

- hydrogen peroxide

…and many more!

Check the chemical compatibility guide

WHICH IS THE BEST TYPE OF PUMP TO CHOOSE?

The GemmeCotti pumps installed on means of transport and involved in the unloading process, permit to direct and move the fluids in total safety, ensuring quick execution.

For this application, GemmeCotti recommends:

- magnetic drive centrifugal pumps series HTM PP/PVDF

- mechanical seal centrifugal pumps series HCO

The design of these two types of centrifugal pumps, permits the safe installation both on land and aboard the vehicle, ensuring a constant flow without the risk of leakage or emissions.

Magnetic pumps series HTM PP/PVDF

Mechanical seal pumps series HCO

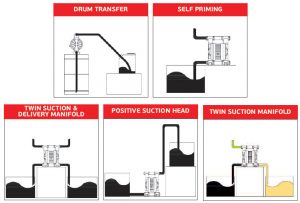

Another practical and effective solution is the use of the GemmeCotti portable pump series H-IBC.

GemmeCotti H-IBC has been designed as a safe and reliable mobile pump specifically for the safe unloading of IBC containers. The unit consists of a magnetic centrifugal pump HTM 10 mounted in a robust carry case, conceived to be easy to move. Thanks to its fast connections, H-IBC is a really flexible solution: the pump could be easily removed from the IBC container and placed in another one according to the requirements. This quick and efficient unit is suitable for several applications. Moreover, the pump is equipped with an electric panel and a start and stop switch for easy, quick and safe use.

Upon request, H-IBC pumps can be supplied in a premium version with wheels, for easier movement and transportation.

Learn more about our portable pumps H-IBC series

HOW TO AVOID THE RISK OF DRY RUNNING DURING THE PROCESS OF TANKERS UNLOADING?

To prevent damages to the pumps due to the lack of liquid, GemmeCotti supplies the dry running protection device. This device is particularly recommended during the operations of tanker unloading and for all the applications in which there is the risk of liquid shortage.

Thanks to the adjustable threshold and timer, it is possible to set up the minimum power and operation time of the device. If the power is lower than the set value, the pump will automatically stop.

Main features of the dry running protection device:

Single Phase CURRENT RELAY

Multirange 15-35A

2 set points MAX / min

Also for motors with INVERTER

More information about the device

MAGNETIC DRIVE CENTRIFUGAL PUMPS AND MECHANICAL SEAL PUMPS

It is fundamental to choose the right pump model when dealing with acids or corrosive liquids. For the operations of tanker unloading, GemmeCotti suggests the use of mechanical seal centrifugal pumps or magnetic centrifugal pumps. The type of pump is selected according to the liquid to be pumped and to the requested working point.

operations of tanker unloading, GemmeCotti suggests the use of mechanical seal centrifugal pumps or magnetic centrifugal pumps. The type of pump is selected according to the liquid to be pumped and to the requested working point.

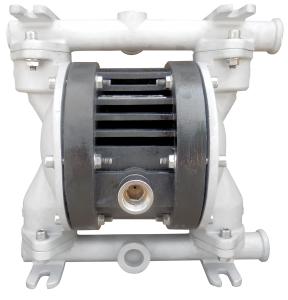

MAGNETIC DRIVE CENTRIFUGAL PUMPS

Mag drive pumps have a sealless design that is particularly suitable to pump corrosive and dangerous liquids; the magnetic design together with the usage of anticorrosive materials, guarantees the high chemical resistance and the absence of leakage and emissions.

Moreover, the structure of magnetic drive pumps is really simple and requires very little maintenance with a consequent saving in terms of repairs and spare parts expenses during the pump life. The external magnet placed on the drive shaft transmits the motion to the internal magnet connected to the impeller, which rotates and moves the fluids through the pump.

MECHANICAL SEAL PUMPS

Mechanical seal centrifugal pumps are the best solution when the liquid has solids in suspension: their design with open impeller permits to transfer dirty liquids and fluids with high viscosity.

The seal of these pumps is composed of a static ring and a rotating ring placed on the pump shaft, which is directly coupled to the motor shaft. When the pump is working, the two rings’ surfaces slide together and the lubrication of the parts is granted by the pumped liquid.

GemmeCotti supplies pumps for chemicals suitable for the offloading process of tanker trucks, petrol tankers and railroad tank cars. Our industrial pumps allow you to unload the fluids with the maximum efficiency, ensuring safety, reliability and saving in terms of repairs and spare parts expenses.

Upon request, GemmeCotti pumps can be supplied with single phase motors and in ATEX version for potentially explosive areas.

Contact us: info@gemmecotti.com

Our sales department is available from Monday to Friday, from 8.30 to 12.30 and from 12.30 to 14.00, to select the best chemical pump for your needs.