In applications where chemicals, acids and corrosive liquids are involved it’s necessary to pay a great attention to the kind of pumps used and sometimes it’s difficult to choose between seal or sealless pumps. So which are the advantages and disadvantages of mag drive sealless pumps in comparison a with mechanical seal pumps? This is the neverending debate for pump manufacturers and pump users and in this article I would like to point out some aspects to keep in mind when choosing the pump design.

MAG DRIVE PUMPS

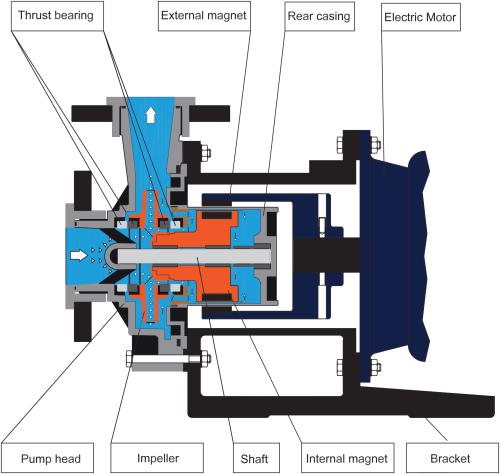

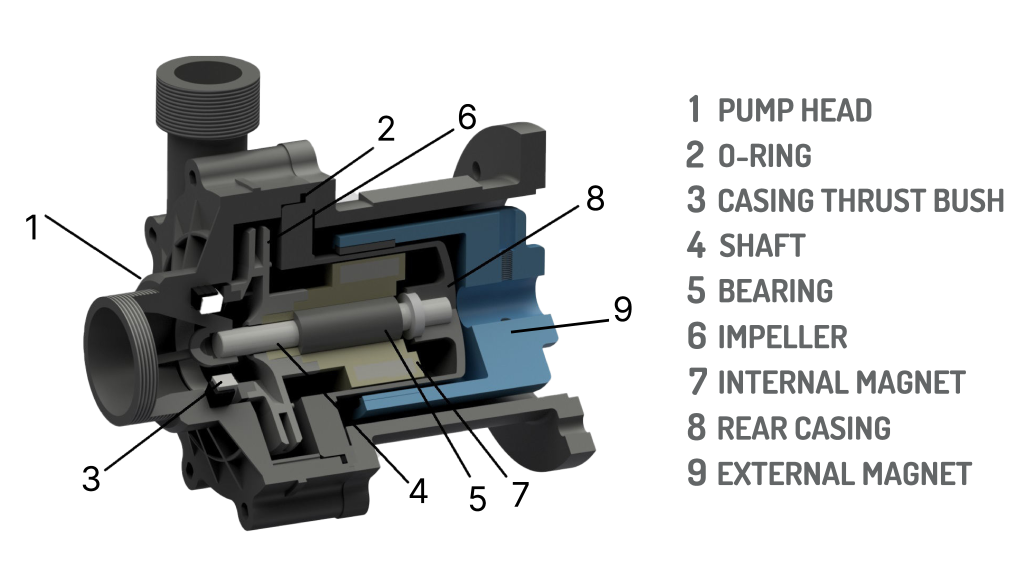

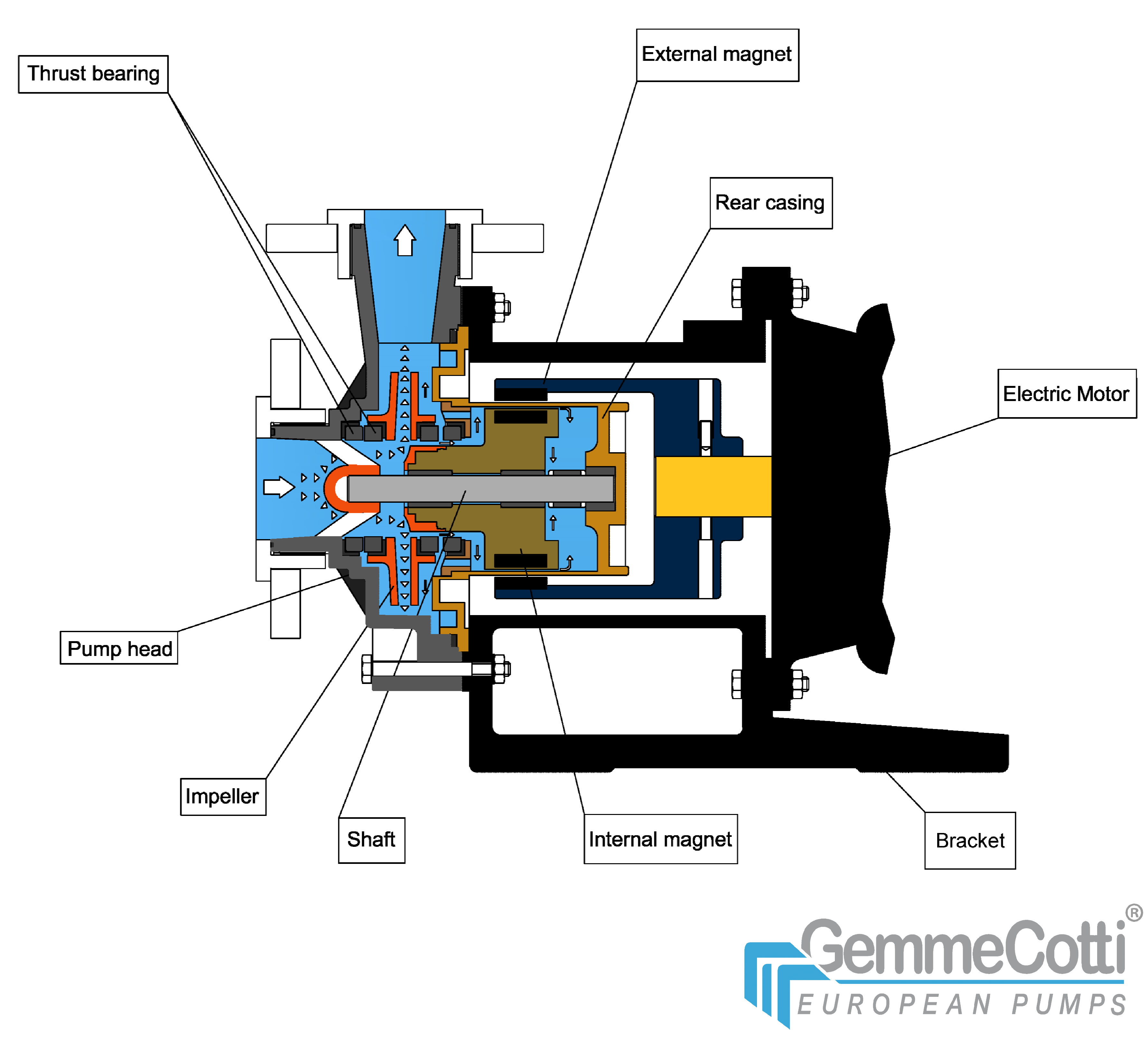

Mag drive pumps have a particular sealless design where the pump is closed coupled to the motor. The external magnet placed on the drive shaft transmits the motion to the internal magnet connected to the impeller which rotates and moves the fluid through the pump. The external magnet and inner magnet are separated by a rear casing that creates a hermetic containment of the liquid that has no access to the outside

Advantages

- This special hermetic pump design prevents any leakage of fluid and fugitive emissions, that in case of chemicals, corrosive liquids, explosive and flammable fluids could be very dangerous for people dealing with the pump and especially for the environment. So mag drive pumps allow to follow strict environmental and safety objectives required by many regulations. We shouldn’t forget also that some liquids could be very expensive and their loss due to a seal failure may cause high unnecessary extra costs.

- Mag drive pumps are very reliable and need very low maintenance thanks to their simple design. With normal working conditions these pumps can work without any kind of repair for more than a decade so their life cost is highly reduced even if it’s always better to check o-rings and bearings every one/two years just to be sure that there is no wearing.

- The coupling is very easy because there is no need for a motor/pump alignment.

Disadvantages

- In applications involving even a small percentage of solids the mag drive system is not the suitable solution. Magnetic drive pumps, in fact, can work only with clean liquids without solids in suspension.

- Magnetic drive pumps are usually more expensive than mechanical seal pumps. However, as written above, the maintenance costs are very reduced during the life of the pump and these long-term financial advantages should be considered when choosing the pump design.

MECHANICAL SEAL PUMPS

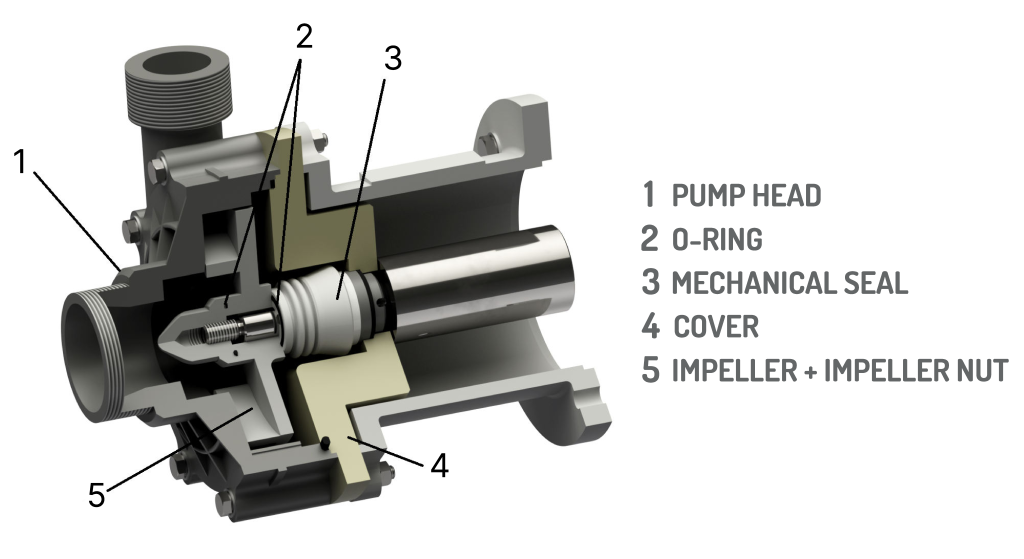

The seal in mechanical seal pumps is composed by a static ring and a rotating ring placed on the pump shaft which is directly coupled to the motor shaft. The two surfaces sliding together need to be lubricated and the seal lubricant is the liquid itself that is being pumped.

Advantages

- Mechanical seal pumps are the perfect solution for applications involving solids in the liquid (for example waste water treatments) because their design with open impeller allows to pump very dirty liquids and fluids with high viscosity.

- The cost of this kind of pumps is lower in comparison with mag drive pumps so, if the financial aspect is critical when choosing the pump, sealed pump may be the right selection.

Disadvantages

- Seals are often the weak point in standard pumps because they are the first cause of failure in a chemical process. When a mechanical seals fails it allows the liquids to escape causing dangerous leakage.

- Considering the point above, to avoid harmful events and dangerous leakage it’s necessary to plan a periodical maintenance of mechanical seal pumps to check the status of the seal and replace worn parts. In this case the costs of maintenance of these pumps could be higher than those of mag drive pumps.

In some applications it’s possible to install both mechanical seal or mag drive pumps and technicians can decide according to the advantages and disadvantages of each pump which is the best for them.